Optimizing Quick Step Saw QS2500/4500/7000

Equipped with patent optimizing software, QUICK STEP SAW QS2500/4500/7000 is design for high precision requirement working condition, and it is easy and safe to operate.

OPTIMIZING QUICK STEP SAW QS2500/4500/7000

UNION BROTHER have developed series of optimizing cross cut saws, based on different requirement of wood working manufacturing process. From PLC control, computer software control, to intelligent system solutions. QS2500/4500/7000 is designed for full optimizing such as length optimizing, quantity optimizing, value optimizing, grade optimizing, etc.

Cross cutting is very crucial in wood machining process, the Optimizing Cross Cut Saw will bring a fundamental innovation compare with the manual cutting. It will reduce the timber waste and prevent the potential risks to the operators.

Advantages

● Remove the defeats (burl, crack, head and end) marked on the timber.

● Measuring and optimizing then cutting off, with high accuracy

● To minimize the working load of the operators.

● Single or multi-pieces cutting available

● Ink-jet printing on the pieces

● To provide many optimizing modes, flexible for choose.

Applications

● Wood furniture

● Wood door

● Wood material preparation

● Laminated wood

Related products

-

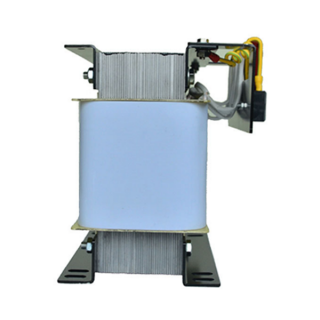

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Waste Tyre Recycling Production Line

Contact UsPresently, waste tire recycling equipment provided by our domestic competitors usually can produce 20-40 meshe rubber powder under normal temperature.

-

Optimizing Cross Cut Saw MAXCUT CS15/15XL

Contact UsMAX CUT CS15/15XL, as a relatively practical type of cross cut saw, it is designed for the bending timber, such as rubber wood.

Reviews

There are no reviews yet.