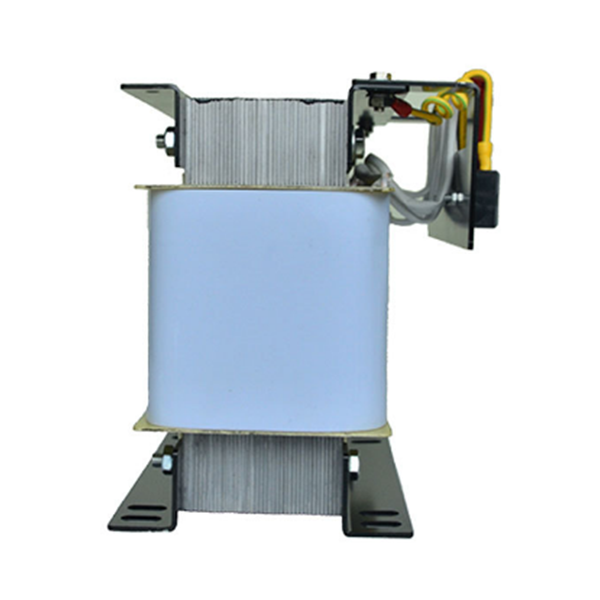

Dry type transformer

Safe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

Safe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free; It has good heat dissipation performance, strong overload capacity, and can increase capacity operation when forced air cooling; good moisture-proof performance, suitable for operation in high humidity and other harsh environments; dry-type transformers can be equipped with complete temperature detection and protection systems. It adopts an intelligent signal temperature control system, which can automatically detect and display the respective operating temperatures of the three-phase windings. It can automatically start and stop the fan, and has functions such as alarm and trip settings. It is small in size, light in weight, takes up less space, and reduces installation costs. Low.

What is a Dry Type Transformer?

A dry type transformer is an electrical device that uses air or a gaseous medium for insulation and cooling, as opposed to liquid-filled transformers that use oil. This design eliminates the risk of oil leaks and associated environmental hazards, making it an ideal choice for indoor installations and areas with high safety and environmental standards.

Key Features

-

Safety and Fireproof Characteristics

Our dry type transformers are inherently safe and fireproof. They do not use any flammable liquids, significantly reducing the risk of fire hazards. This makes them suitable for installation in load centers without the need for additional fire safety measures.

-

Environmental Compatibility

Designed with the environment in mind, our transformers are non-polluting. They do not release harmful substances into the environment, ensuring a cleaner and safer operation.

-

Mechanical Strength and Reliability

Utilizing domestic advanced technology, our transformers boast high mechanical strength and strong short-circuit resistance. This ensures a long service life and high reliability, even under challenging conditions.

-

Thermal Stability and Low Loss

With excellent thermal stability, our dry type transformers operate efficiently with low losses. This contributes to energy savings and reduced operational costs.

-

Noise Reduction

Our transformers are designed to operate with low noise levels, making them suitable for use in noise-sensitive environments.

-

Maintenance-Free Operation

One of the standout features of our dry type transformers is their maintenance-free operation. There is no need for regular inspections or maintenance associated with liquid-filled transformers, saving time and resources.

-

Heat Dissipation and Overload Capacity

Our transformers have excellent heat dissipation performance and strong overload capacity. They can operate at increased capacity when subjected to forced air cooling, ensuring uninterrupted power supply during peak loads.

-

Moisture Resistance

Suitable for operation in high humidity environments and other harsh conditions, our transformers are designed to withstand moisture, ensuring reliable operation in diverse climates.

-

Intelligent Temperature Control System

Equipped with an intelligent signal temperature control system, our transformers can automatically detect and display the operating temperatures of the three-phase windings. This system includes features such as automatic fan control, alarm settings, and trip functions, enhancing safety and reliability.

-

Compact Design and Cost-Effective Installation

Our dry type transformers are compact and lightweight, requiring less space and reducing installation costs. This makes them an economically viable option for a wide range of applications.

Applications

Our dry type transformers are suitable for a wide range of applications, including but not limited to:

-

Industrial and commercial buildings

-

Residential complexes

-

Public facilities such as schools and hospitals

-

High-occupancy buildings like shopping centers and airports

-

Renewable energy systems

-

Telecommunication infrastructure

-

Data centers

Chengdu Chengling Technology Co., Ltd.'s dry type transformers represent the pinnacle of safety, efficiency, and environmental responsibility. With a focus on innovation and quality, our transformers are designed to meet the diverse needs of modern power distribution. Whether it's for a small commercial setup or a large industrial complex, our dry type transformers offer a reliable and cost-effective solution for your power needs.

Related products

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

High-efficiency activated carbon attachment device

Contact UsHigh-efficiency activated carbon attachment device can quickly absorb pollutants in exhaust gas. The exhaust gas containing pollutants is powered by a fan and enters the activated carbon adsorber under negative pressure.

-

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

Reviews

There are no reviews yet.