https://www.cronusgr.com/New-Energy

https://www.cronusgr.com/Cold-Plate-for-New-Energy.html

CNC Coolers: Precision Cooling for Optimal Performance

Our CNC coolers are meticulously engineered to deliver precision cooling, ensuring that your new energy systems operate at peak efficiency. These coolers are crafted using state-of-the-art CNC (Computer Numerical Control) technology, which allows for unparalleled precision and accuracy in manufacturing. This results in coolers that are not only highly efficient but also incredibly reliable, capable of withstanding the rigors of continuous operation in demanding environments.

Wuxi Cronus New Industry Co., Ltd. is a CNC cooler exporter and supplier.

Features of Our CNC Coolers:

1. Advanced Design: Our coolers are designed with intricate geometries that maximize heat dissipation, ensuring that your systems remain cool even under heavy loads.

2. Durable Construction: Built with high-quality materials, our CNC coolers are designed to last, providing you with a long-term solution for your thermal management needs.

3. Customizable Solutions

4. Efficient Heat Transfer: Our coolers are engineered to facilitate rapid heat transfer, keeping your systems at optimal operating temperatures.

5. Compatibility: Designed to integrate seamlessly with a wide range of new energy applications, our CNC coolers are the perfect choice for enhancing the performance and longevity of your equipment.

Applications in the New Energy Sector

Our CNC coolers are ideal for various applications within the new energy sector, including but not limited to:

– Solar Power Systems: To maintain the efficiency of solar panels and associated electronics.

– Wind Turbine Components: For cooling the electrical and mechanical components of wind energy systems.

– Electric Vehicle Chargers: To ensure the reliability and longevity of EV charging infrastructure.

– Energy Storage Systems: For managing the heat generated in battery storage systems.

Why Choose Wuxi Cronus for Your Thermal Management Needs?

– Innovation: We are committed to pushing the boundaries of what's possible with our thermal management solutions.

– Quality: Our products are manufactured to the highest standards, ensuring reliability and longevity.

– Customer Focus: We prioritize your needs, offering tailored solutions that meet your specific requirements.

– Sustainability: We are dedicated to creating products that contribute to a more sustainable future.

Related products

-

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

-

PP PE LDPE HDPE Film Recycled Plastic Washing Machine Recycling Production Line For Sale

Contact UsThe recycling washing line is mainly used to recycle all kinds of plastics, such as film, agricultural film, greenhouse film, woven bags and etc. it can also recycle waste plastic bottles such as HDPE, LDPE, PP, etc. Our output ranges from 300 kg to 2000 kg per hour. Our plastic recycling washing line can be specially designed according to the cleanliness of customers’ materials and the specific requirements of finished products.

-

Optimizing Cross Cut Saw MAXCUT CS15/15XL

Contact UsMAX CUT CS15/15XL, as a relatively practical type of cross cut saw, it is designed for the bending timber, such as rubber wood.

-

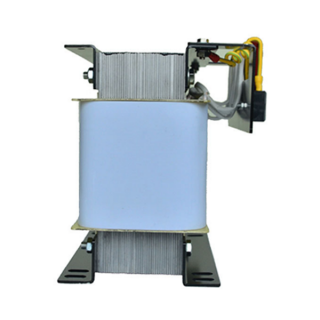

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

Reviews

There are no reviews yet.