Small EDM Wire Cut Machine

Economic high speed edm wire cut machine.

Main Features:

Roller for X/Y axis, also called hard rail ( V rail);

With ±3° taper as standard, ±15°, ±30°, ±45° as option;

Accuracy: ±0.01/300mm;

Roughness: Ra 1.0-2.5 µm;

Low consumption, material saving.

Technical Parameters:

| Model | DK7720 | DK7725 | DK7735 | DK7745 |

| Table size (mm) | 490*380 | 580*400 | 740*470 | 830*570 |

| X*Y travel (mm) | 250*200 | 320*250 | 450*350 | 550*450 |

| Max. Z travel (mm) | 200 | 250 | 400 | 500 |

| Max. workpiece weight (kg) | 200 | 250 | 350 | 450 |

| Cutting speed (mm2/min) | Standard cutting speed:110-120, Max. cutting speed: 160-180 | |||

| Dimension L*W*H (mm) | 1200*900*1300 | 1300*1100*1500 | 1500*1200*1650 | 1700*1350*1700 |

| Net weight (kg) | 750 | 900 | 1100 | 1250 |

Main Features:

Roller for X/Y axis, also called hard rail ( V rail);

With ±3° taper as standard, ±15°, ±30°, ±45° as option;

Accuracy: ±0.01/300mm;

Roughness: Ra 1.0-2.5 µm;

Low consumption, material saving.

Different controller and different software:

a) High speed single cutt controller;

b) Multi-cut controller ( which improve the accuracy and finish);

Software: AUTOCUT, X8, HL, HF.

All kinds of voltage: 220/380/415/440V

Company & Workshops

BOFENG Machinery is a group with 4 factories. BOFENG has about 60000 square

meter work shop.

Production Equipments

The main parts of our machines are processed by cnc machine. We have gantry

type cnc milling machine, cnc vertical machining center, gantry type cnc

grinding machine, cnc laser cutting machine, cnc bending machine, cnc shearing

machine.

Test & Inspection

All machines will be tested before shipment.

Package & Delivery

Related Products

DK7735 DK7745 Fast Speed Wire EDM Machine

DK7750 DK7750F Wire EDM Machine

DK7763 DK7763F EDM Cutting Machine

BF350C BF450C Heavy Dudy High Precision Edm Wire Cut Machine

BF500C BF630C High Precision Edm Wire Cut Machine

Middle Speed EDM Wire Cut Machine

BF320C BF400C Multi Pass EDM Wire Cut Machine

BF350T EDM Wire Cutting Machine

BF450T EDM Wire Cutting Machine

Related products

-

PP PE LDPE HDPE Film Recycled Plastic Washing Machine Recycling Production Line For Sale

Contact UsThe recycling washing line is mainly used to recycle all kinds of plastics, such as film, agricultural film, greenhouse film, woven bags and etc. it can also recycle waste plastic bottles such as HDPE, LDPE, PP, etc. Our output ranges from 300 kg to 2000 kg per hour. Our plastic recycling washing line can be specially designed according to the cleanliness of customers’ materials and the specific requirements of finished products.

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

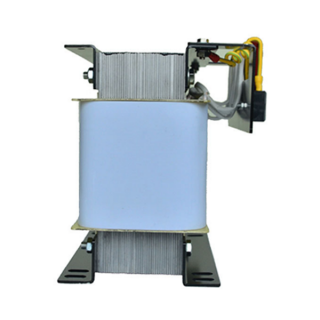

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

Reviews

There are no reviews yet.