Semi-automatic Hub Bearing Unit Assembly Line

● SMALL FOOTPRINT / QUICK CHANGEOVER / FLEXIBLE OPERATION / DATA TRACEABILITY

● FREE COMBINATION / SIMPLE OPERATION

Product Introduction

Quality Assurance / Long Warranty / Worry-free Operation

-

Product Name: Semi-automatic Hub Bearing Unit Assembly line

-

Advantage: The production line work pace of 15-18 seconds per set(Non-manual participation).

-

Features: Free combination of processes, small footprint and quick changeover.

Some Details

Intelligent / Green Practitioner

|

1: Out Ring Grease Injection Machine Automatical and uniform grease injection High-precision grease injection No residue |

2: NEGATIVE CLEARANCE DETECTION MACHINE AUTOMATIC OPERATION VISUAL DISPLAY HIGH-PRECISION MEASUREMENT |

3: END-HOP DETECTION MACHINE RAPID DETECTION VISUAL DISPLAY STRONG ADAPTABILITY AND VERSATILITY |

|

|

|

CASE SHOW

High Efficiency / High Precision / High Quality

Related products

-

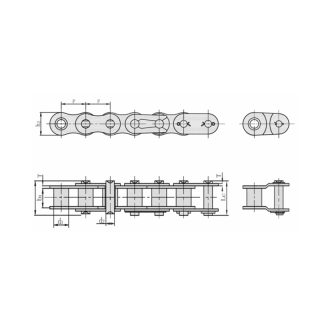

Short pitch precision roller chains(A series)

Contact UsShort pitch precision roller chain, also known as A series roller chain, is a type of roller chain characterized by small pitch and precise construction. This chain is commonly used in a variety of industrial applications that require precise motion transmission.

-

380V Strong Power Strong Adaptability Hand-Held Concrete Floor Grinder

Contact UsHigh efficiency and energy saving dynamic system,compact and sophisticated manufacturing technology.

-

Precision Milling parts Processing Service

Contact UsMachining Equipment:CNC lathe/Wire cutting/Surface grinder/Milling maching latheDrilling machining/Horizontal saw.

-

INDUSTRIAL DIRECT GAS FIRED TUNNEL OVEN

Contact UsSuitable for a variety of products baking, there are several choices for the type of transporting belt, you can choose the best type based on the products to be baked.

Reviews

There are no reviews yet.