INDUSTRIAL DIRECT GAS FIRED TUNNEL OVEN

Suitable for a variety of products baking, there are several choices for the type of transporting belt, you can choose the best type based on the products to be baked.

Equipment Function of Direct Gas Fired Tunnel Oven

♦ Suitable for a variety of products baking.

♦ There are several choices for the type of transporting belt, you can choose the best type based on the products to be baked.

♦ Reinforced high-temperature resistant conveyor chain, equipped with automatic lubricating device.

♦ Heated by pipe ribbon burner, proportional PID temperature control, small thermal inertia and high temperature control accuracy.

♦ Forced convection system makes the product heat more uniform with bright color.

♦ Frequency controlled exhaust system exhausts heat under the appropriate moisture requirement, which energy saving and environmental protection achieved.

Specification of Direct Gas Fired Tunnel Oven

| SPECIFICATIONS | INNER WIDTH | PASSING HIGHT | EXTERIOR WIDTH | RATED THERMAL POWER | NORMAL HEAT CONSUMPTION |

| Tray size: W600 × H400mm | mm | mm | mm | kcal/m | kcal/m |

| Two trays | 1400 | 220 | 2250 | 12000 | 6000 |

| Three trays | 2000 | 220 | 2850 | 17200 | 8600 |

| Four trays | 2650 | 220 | 3700 | 22400 | 12000 |

Product Category of Direct Gas Fired Tunnel Oven

Related products

-

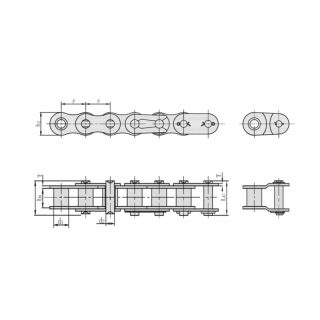

Short pitch precision roller chains(A series)

Contact UsShort pitch precision roller chain, also known as A series roller chain, is a type of roller chain characterized by small pitch and precise construction. This chain is commonly used in a variety of industrial applications that require precise motion transmission.

-

Power Conducting Arm

Contact UsPower Conducting Arm is the clamping arm for EAF Electric Arc Furnace Industrial Electrode Arm With Copper Clad Explosion Plate

-

OIL SPRAY MACHINE

Contact UsGuangdong Baimai Equipment Technology Company was established in Dongguan, the city is located in China’s global bay area “Guangdong-Hong Kong-Macao Greater Bay Area”, known for its manufacturing.

-

OR Raceway Grinder for Hub Generation 2&3 Bearings

Contact UsAPPLICABLE PRODUCTS: HUB GENERATION 2&3 BEARINGS

Reviews

There are no reviews yet.