https://www.gdlbtech.com/LED-UV-Machine.html

LBUV-906MD double-sided UV machine

1.Equipment overview

Mainly used for PCB printing drying or UV use before settling tin.

2.Equipment specifications and main technical indicators

Model structure: feed section length 200mm, first UV section 2100mm,

discharge section 200mm, total length 2500mm, total width 1200mm.

UV mode: 6 sets of 9KW lamp, 3 sets up and down each, effective luminous

length 750mm, each lamp can be independently controlled.

Lamp: Imported lamp 9KW UV lamp 6 UV lamps heating time 5min.

Material: internal and external SS41# steel plate after anti-rust treatment

electrostatic spraying 60# light sand color.

Lamp life: the voltage fluctuation is within 5%, and each lighting is more

than 4 hours, and the lamp is guaranteed to be used for more than 1000

hours.

Reflector: Aluminum alloy reflector with new imported titanium-plated

reflective aluminum sheet, high reflection efficiency and light.

Energy requirements: 800mj/spcm(5m/min).

Wavelength: 365nm

Transmission system: motor (made) with gear reducer, sprocket, transmission

network transmission, maximum transmission speed 8M/min, VR stepless speed

regulation, LED digital speed display.

Transmission net: adopt stainless steel polishing wheel+UPE wheel

transmission.

Control panel: man-machine +PLC control (detect no product inflow within 3

minutes, light source into standby state). Safety device: leakage circuit

breaker, overtemperature prevention, transmission motor overload protection,

exhaust motor overload protection, abnormal emergency switch, control line fuse,

etc., in line with international safety standards.

With its innovative double-sided UV curing capability, the LBUV-906MD model stands out as a versatile and efficient equipment, enhancing productivity and ensuring superior quality in the final product.

Key Features and Benefits:

1. Innovative Double-Sided UV Curing : Unlike traditional single-sided systems, the LBUV-906MD offers a dual approach to UV curing, ensuring a more thorough and even drying process across both sides of the PCB.

2. High-Performance UV Lamps : Equipped with six 9KW imported UV lamps, the machine delivers a powerful and consistent UV output. These lamps are strategically positioned to ensure optimal coverage and can be independently controlled for flexibility in operation.

3. Durable Construction : The machine's robust build, featuring internal and external SS41# steel plates treated with anti-rust and electrostatic spraying, guarantees longevity and reliability even in demanding production environments.

4. Extended Lamp Life : With a promise of over 1000 hours of usage under optimal conditions, the LED UV Machine reduces downtime and maintenance costs, ensuring a worthwhile investment for businesses.

5. Efficient Reflector System : The use of an aluminum alloy reflector with imported titanium-plated reflective aluminum sheets ensures high reflection efficiency, maximizing the effectiveness of the UV light output.

6. Optimized Energy Consumption : The machine operates at an energy requirement of 800mj/spcm at a speed of 5m/min, making it an energy-efficient choice for sustainable production processes.

7. Specific Wavelength for Enhanced Curing : Operating at a wavelength of 365nm, the LED UV Machine is tailored to the specific needs of curing processes, ensuring optimal results.

8. Advanced Transmission System : The motor-driven gear reducer, sprocket, and transmission network allow for a maximum transmission speed of 8M/min, with VR stepless speed regulation and LED digital speed display for precise control.

9. High-Quality Transmission Net : The combination of stainless steel polishing wheels and UPE wheels ensures smooth and consistent transmission, reducing the risk of damage to the PCBs.

10. Intuitive Control Panel : The integration of a man-machine interface and PLC control system allows for seamless operation and monitoring, with automatic standby features for energy saving and enhanced safety.

11. Comprehensive Safety Features : The machine is equipped with a range of safety devices, including a leakage circuit breaker, overtemperature prevention, and overload protection for both the transmission and exhaust motors, ensuring compliance with international safety standards.

The LED UV Machine is not just a tool; it's a strategic asset for businesses looking to improve efficiency, reduce costs, and maintain high-quality standards in their production processes. With its double-sided UV capabilities and advanced technological features, the LBUV-906MD is set to become an indispensable part of the modern manufacturing landscape.

Related products

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

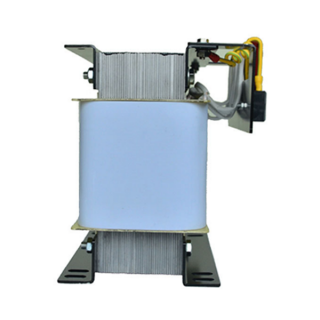

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

-

RO EDI

Contact UsOrisun group is specialize in supplying one stop solutions for whole manufacture chain. developing and manufacturing reverse osmosis water treatment for over 20 years.Our equipment is widely used in pharmacy industry , food and beverage industry , cosmetic industry , chemical industry, etc.As a leading provider of water treatment solutions ,our mission is to supply clean , healthy and safe water for all over the world.

-

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

Reviews

There are no reviews yet.