Gel sealed Mini-pleat HEPA filter(Peripheral gel seals)

The two-component gel is poured into the liquid seal type HEPA filter , and this is used as an installation seal.

The two-component gel is poured into the liquid seal type HEPA filter , and

this is used as an installation seal. This seal form has high reliability and is

suitable for PAO dust detection on site. Mainly used in the end of 0.3μm clean

room and purification equipment in the pharmaceutical industry to control

particles and microorganisms larger than 0.3μm in the clean room or equipment

work area. There are two types of HEPA filter, side sealing and top sealing.

|

Frame |

Aluminum |

|

Spacers |

EVA |

|

Filter media |

Glass fiber |

|

Gasket |

Gel |

|

Operation conditions |

<80%/100%RH.40℃ |

|

Model |

Specification(W×H×D) |

Rated air volume(m3/h) |

Initial resistance(Pa) |

Weighting efficiency(PA) |

Effectiveness@MPPS |

|

CYWGB410.410-93H14 |

410×410×93 |

500 |

220 |

450 |

99.995%≤E<99.9995% |

|

CYWGB550.550-93H14 |

550×550×93 |

1000 |

|||

|

CYWGB650.650-93H14 |

650×650×93 |

1500 |

|||

|

CYWGB750.750-93H14 |

750×750×93 |

2000 |

Related products

-

Gel sealed Mini-pleat HEPA filter(top gel seals)

Contact UsThe two-component gel is poured into the liquid seal type HEPA filter , and this is used as an installation seal.

-

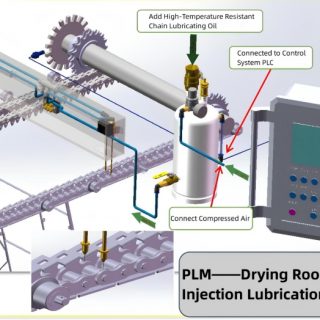

Oil Injector for Drying Room Chain

Contact UsThe oil injection system adopts PLC automatic control.

-

30 tons/day liquid waste +10 tons/day solid waste hazardous waste incineration device

Contact UsThis project intends to build a 30 tons/day liquid waste +10 tons/day solid waste hazardous waste incineration device for Jining Wansheng Environmental Protection Materials Co., LTD., which is used for incineration and treatment of hazardous waste produced by the factory.

-

Polyaluminum Chloride

Contact UsPolyaluminum chloride (drinking water grade) is a kind of inorganic polymer coagulant.

Reviews

There are no reviews yet.