30 tons/day liquid waste +10 tons/day solid waste hazardous waste incineration device

This project intends to build a 30 tons/day liquid waste +10 tons/day solid waste hazardous waste incineration device for Jining Wansheng Environmental Protection Materials Co., LTD., which is used for incineration and treatment of hazardous waste produced by the factory.

|

No. |

Name |

Capacity |

Thermal transfer value |

|

1 |

Solid |

420kg/h |

3000 ~ 4000Kcal/kg |

|

2 |

Liquid |

1250kg/h |

7000 Kcal/kg |

|

No. |

Item |

Unit |

Specification |

Remark |

|

1 |

Average hourly incineration liquid waste |

Kg |

≥1250 |

|

|

2 |

Average hourly incineration solid waste |

Kg |

≥420 |

|

|

3 |

Rotary kiln outlet temperature |

℃ |

850-900 |

|

|

4 |

Secondary chamber outlet temperature |

℃ |

≥1100 |

|

|

5 |

Secondary chamber smoke residence time |

s |

≥2 |

100% load |

|

6 |

Flue gas carbon monoxide concentration |

mg/m3 |

≤100 |

1-hour mean |

|

≤80 |

24-hour mean |

|||

|

7 |

Incineration efficiency |

% |

≥99.9 |

|

|

8 |

Incineration removal rate |

% |

≥99.99 |

Persistent organic pollutants ≥ 99.9999 |

|

9 |

Thermal reduction rate of incineration residue |

% |

<5 |

100% load |

|

10 |

Daily capacity |

ton |

40 |

|

|

11 |

Annual running time |

day |

≥300 |

|

|

12 |

Oxygen content of flue gas at the the secondary chamber outlet |

% |

6-10 |

Dry flue gas |

|

13 |

Heat conduction oil furnace outlet flue gas temperature |

℃ |

300±25 |

|

|

14 |

Bag inlet and outlet temperature difference |

℃ |

≤10 |

|

|

15 |

Velocity of filtering |

m/min |

0.4-0.6 |

Normal operation |

|

16 |

Annual running time |

h |

≥7200 |

|

|

17 |

Overall engineering system availability |

% |

100 |

|

|

18 |

Range of load variation |

% |

70-110 |

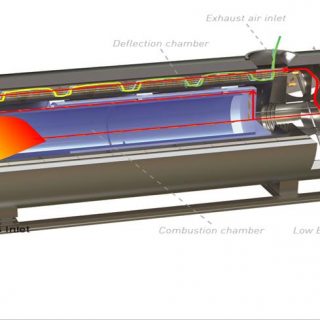

Automatic delivery system——automatic feeding system——rotary kiln (separate kiln tail cover)——secondary chamber——SNCR denitrification system——Waste heat conduction oil boiler——quench deacidification tower——dry spray tower——bag dust collector——induced draft fan——SCR system——spray washing tower——packing tower——Wet electrostatic dust removal——chimney

Related products

-

External Suction Arm

Contact UsFeatures:

● Persistent tightness

● Arm keeps position due to self-supporting design

● Fast operation due to particularly flexible adjustment

● User-friendly due to particularly smooth movement of the hood with one hand

● Various options to connect the exhaust arms to fans, stationary devices or via duct work to central extraction and filtration systems -

KPR Zeolite Rotary Concentrator

Contact UsUnder low temperature conditions, high air volume organic waste gas passes through the KPR Zeolite Rotary Concentrator, and VOC molecules adsorb its surface.

-

TNV direct fired incinerator

Contact UsDesign and manufacture by using the German EN12753 safety standard and the European ED. It is used Metal Painting and Printing LED Drying:

1. For stable industrial and mining conditions with a high temperature concentration of 1.5g/M3 or above.

2. Industrial and mining conditions with requirements for thermal energy recovery and utilization.

3. Industrial and mining conditions required for the operation of independent drying rooms.

4. Special effects on projects that reduce emissions and increase production -

PP Rainwater Module 50T(Green)

Contact UsPP plastic modules are injection-molded from polypropylene. By enveloping the structure with a composite geotechnical membrane, the system can function as either a storage reservoir.

Reviews

There are no reviews yet.