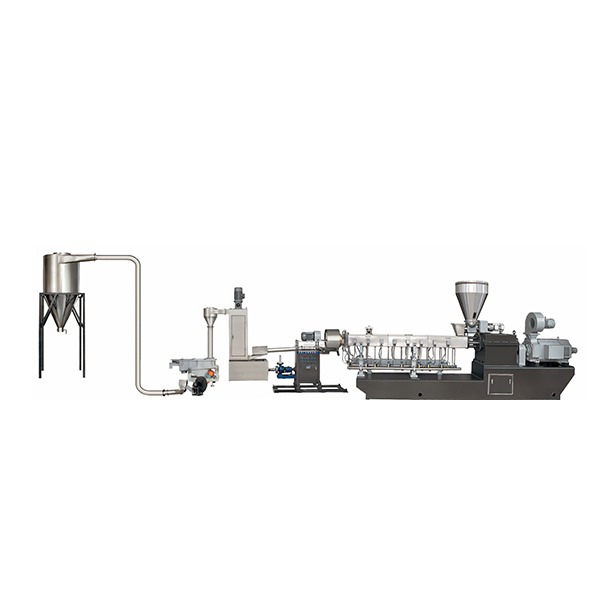

Compounding and Water-Ring Hot-Face Pelletizing Iine of Filled System and Polymer Blends

Mold surface water-ring pelletizing is suitable for most filled or unfilled thermoplastic materials. Since the water ring is formed on the periphery of the template

Filling, Compounding and Water-Ring Hot-Face Pelletizing Ine of Filled System

and Polymer Blends

Mold surface water-ring pelletizing is suitable for most filled or unfilled

thermoplastic materials. Since the water ring is formed on the periphery of the

template, the template does not contact the cooling water. This feature ensures

the uniformity of the template temperature. In this way, even if the output is

very low, the template

discharge is still very uniform and normal. Due to the color mold surface hot

cutting system, not only the appearance of the material particles is guaranteed

to be smooth and beautiful, but also because the pellets are cut out and put

into the cooling water ring in time, the equipment structure is compact and the

equipment space is reduced.

The relatively simple equipment configuration of this process includes:

cutting machine, dehydrator, air conveying system and silo. Users can also

select boiling bed according to process needs. Vibrating screen and other

equipment. The mold surface water ring pelletizing system includes vertical

water ring pelletizing system and horizontal water ring pelletizing system.

Scope of application

lPE, EA, etc. + calcium carbonate, talc, titanium dioxide, carbon black and

other filler modification;

lLDPE, HDPE, LDPE.MDPE sheath materials. Insulation materials; radiation

cross-linked materials, optical cable coating materials, heat shrinkable tube

materials and other electrical materials

lPPR tube materials, PE cross-linked tube materials: TPR, TPU, TPV and other

thermoplastic elastomers, EVA and hot melt adhesives, etc.

lPE, ABS, PS, EVA and other masterbatches: ABS.EVA and other flame retardant

masterbatches; PE, PP, PS and other filler degradation masterbatches

Related products

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Small EDM Wire Cut Machine

Contact UsEconomic high speed edm wire cut machine.

Main Features:

Roller for X/Y axis, also called hard rail ( V rail);

With ±3° taper as standard, ±15°, ±30°, ±45° as option;

Accuracy: ±0.01/300mm;

Roughness: Ra 1.0-2.5 µm;

Low consumption, material saving. -

-

Used NSC Schlumberger GN6 Gilling Machine

Contact UsYear: 1986

Spinning production line

Mixed belt: GN6 solid ball forming machine barrel

One needle: GN6 cylinder diameter 700 * 1000mm, 1 head and 1 cylinder, self leveling

Two needles: GN6 cylinder diameter 700 * 1000mm, one head and one cylinder

Three needles: GN6 cylinder diameter 600 * 1000mm, 2 heads and 2 cylinders

According to your requirements, we can transform it into a size suitable for your production needs!

Reviews

There are no reviews yet.