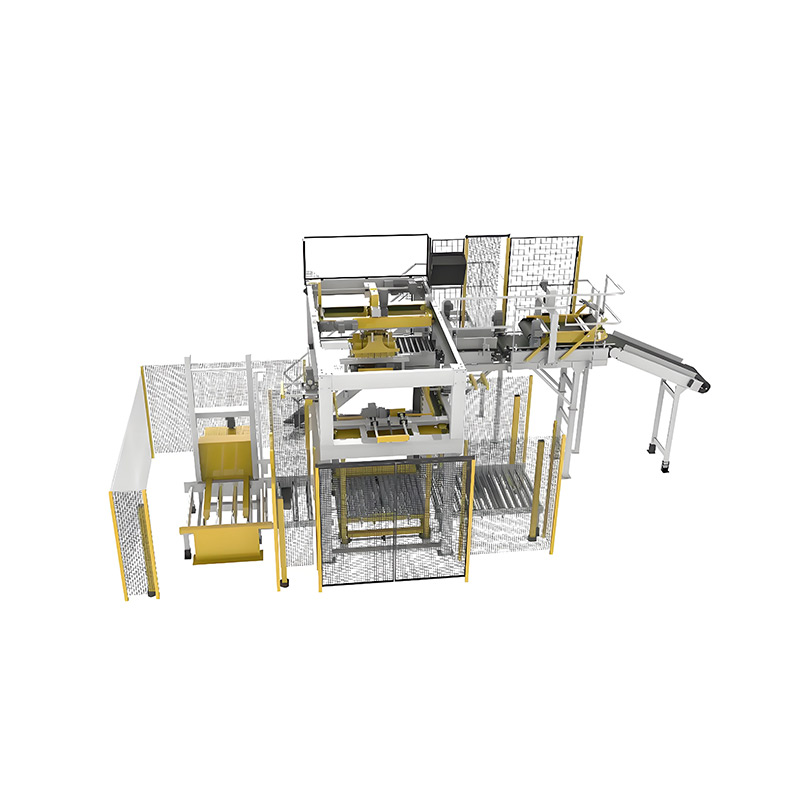

Compact Palletizer

The Compact Bag Palletizer uses an ideal combination of robotic and conventional palletizing technologies to optimize the benefits of both systems and create square and sturdy pallets.

General Introduction:

The Compact Bag Palletizer uses an ideal combination of robotic and

conventional palletizing technologies to optimize the benefits of both systems

and create square and sturdy pallets. The innovative automatic gripper ensures

precise bag positioning for maximum stability, while the palletizer's compact

design and optional modules make it easy to adapt to your available space. With

options for low-level or high-level infeed conveyor, the compact palletizer

suits any pallet material and bag type for use in all common industries.

Working Process:

§ The empty pallets previously loaded into a magazine are automatically

conveyed to the palletizer where they are positioned by a mechanical lifter

under the sliding table.

§ A belt conveyor (not part of the palletizer) transports the bags from the

bagging line to the infeed roller conveyor of the palletizer. The bag lift

transfers the bag to the gripper and descends again to pick up another bag.

§ The bag is taken by the gripper and then moved towards a position preset by

the palletizing program. While positioning the bag, the gripper can move by 90°

and 180° in both directions.

§ The layer is formed by positioning the bags individually onto the sliding

table. As soon as the layer is completed, the lateral guiding plates are closed

for layer forming. They can be controlled via operator panel and are adjusted to

the respective palletizing program. After the layer has been formed the sliding

table opens in the middle and transfers the layer onto the pallet. The sliding

table closes again.

§ For more stability and layer compaction, the pallet lift moves upwards,

pressing the layer against the closed sliding table. The pallet lift then

descends until it reaches the transfer level for the next layer.

§ The loaded pallet is conveyed to the pallet outfeed by means of a roller

conveyor installed on the elevator.

Product Feature:

§ Versatile and performant: Handles wide range of bag sizes and pallet

patterns; Precisely positions bags with automatic gripper techniques; Overlaps

bags and forms and presses layers for increased stability; Possible to upgrade

capacity

§ High-quality design: Heavy-duty construction for a longer life span;

Compact design with low-level infeed entry; Multiple layout configurations;

Optional additional modules and variable layout configurations; Built-in energy

savings (Motor iE3 and weight reduction on gripper); Quick installation;

§ Reliable and safe; Handrails on top frame allow easy and safe access into

machine; Automatic safety latches on elevator; User-friendly with low

maintenance requirements;

Specifications:

|

Max Speed |

500~800 bags/h |

|

Workable Bag Weights |

20~50KGS/Bag |

|

Min. Pallet dimensions |

1200 x 800 mm |

|

Max. Palletized Height |

2400mm(Pallet height included) |

|

Max. Full Pallet Weight |

2000KGS |

|

Power Supply |

220/380 V – 50 Hz |

FAQ:

1. Why compact palletizer might be your palletizing solution?

Compact palletizers are designed to optimize space utilization in your

facility. With their small footprint, they require minimal floor space, allowing

you to make the most of your production area.

Their compactness also makes them suitable for integration into existing

production lines without major modifications.

2. Do compact palletizers require extensive maintenance?

Compact palletizers are built to be durable and reliable. While routine

maintenance is necessary, it is minimal compared to the benefits gained from

using a compact palletizer. Regular maintenance tasks include cleaning,

lubrication, and periodic inspections to ensure optimal performance.

3. Can a compact palletizer reduce product damage during palletizing?

Absolutely! Compact palletizers ensure precise stacking and secure pallet

loads, reducing the risk of product damage during transportation.

4. How does a compact palletizer contribute to increased productivity?

Compact palletizers automate the palletizing process, minimizing manual labor

requirements and allowing for faster and more efficient palletizing

operations.

Related products

-

High-efficiency activated carbon attachment device

Contact UsHigh-efficiency activated carbon attachment device can quickly absorb pollutants in exhaust gas. The exhaust gas containing pollutants is powered by a fan and enters the activated carbon adsorber under negative pressure.

-

Optimizing Cross Cut Saw MAXCUT CS15/15XL

Contact UsMAX CUT CS15/15XL, as a relatively practical type of cross cut saw, it is designed for the bending timber, such as rubber wood.

-

MA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment

Contact UsMA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment can process the slitting of the coil with different sizes to small strips for processing various kinds of metal coil materials.

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

Reviews

There are no reviews yet.