Casting part

Machining Equipment:CNC lathe/Wire cutting/Surface grinder/Milling maching latheDrilling machining/Horizontal saw.

|

Item Name |

Our processing services |

|

Machining Equipment |

CNC lathe/Wire cutting/Surface grinder/Milling maching latheDrilling machining/Horizontal saw. |

|

Materials |

Aluminum Alloy:5052/6061/6063/7075 etc |

|

Brass Alloy:3602/2604/h59/h62/etc |

|

|

Stainless Steel Alloy:303/304/316/412/etc |

|

|

Steel Alloy:Carbon/Die Steel/etc |

|

|

Other Special Materials:Lucite/Nylon/Bakelite/etc |

|

|

We handle many other type of materials. Please contact us if your required material is not listed above. |

|

|

Sureface treatment |

Passivation |

|

Polish |

|

|

Heat-disposing |

|

|

Anodizing |

|

|

Sand blasting |

|

|

Hot-dip galvanizing |

|

|

Electroplating(color, blue, white, black zinc, Ni, Cr, tin, copper, silver) |

|

|

Black oxide coating |

|

|

Rust preventive oil |

|

|

Quality Assurance |

ISO9001:2008 Certified.TUV |

|

Process capability |

We are able to supply sheet metal, mechanical parts machining, surface treatment such as anodize and plating according to our customers' requirement. |

|

serviceablerange |

Parts are used onvehicles, printing machines, food processing machines, textile machines, electronic machines, etc. |

|

Exported To |

Japan, America, Canada, England and BelgiumGermany, Russia, France, Italy, and all countries |

|

Application |

Machine spare parts,Motor Machinery Electric Tools,Sports Apparatus,kitchenware,office equipment,Scooter Aluminium windows,Shower blocks,hanging round,closet wheel,toys.etc |

1、Production and processing

2、Surface treatment

3、Quality Inspection

4、Packaging and Shipping

Related products

-

Automatic Online Steel Wire Annealing furnace

Contact UsAnnealing Furnace advantage: For high carboin wire,low carbon wire,annealing furnace. For Annealing steel wire size 0.7mm~1.6mm;1.6mm~4.0mm; 4.0~8.0mm;Annealing for steel wire 20lines ,30lines…

-

OIL SPRAY MACHINE

Contact UsGuangdong Baimai Equipment Technology Company was established in Dongguan, the city is located in China’s global bay area “Guangdong-Hong Kong-Macao Greater Bay Area”, known for its manufacturing.

-

Customized heatsink

Contact UsSurface Finish:Powder Coating, Anodizing, Brushing, Polishing, Electric-plating,powder Coating, Hot Dip Galvanizing, E-coating, Tin Plating,Nickel Plating, Chrome Plating,Decorate, Enamel Coating etc.

-

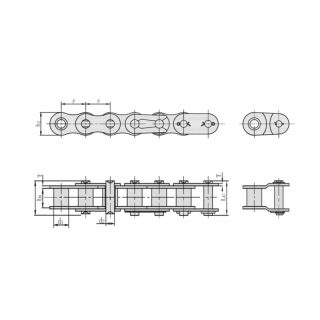

Short pitch precision roller chains(A series)

Contact UsShort pitch precision roller chain, also known as A series roller chain, is a type of roller chain characterized by small pitch and precise construction. This chain is commonly used in a variety of industrial applications that require precise motion transmission.

Reviews

There are no reviews yet.