Automatic Online Steel Wire Annealing furnace

Annealing Furnace advantage: For high carboin wire,low carbon wire,annealing furnace. For Annealing steel wire size 0.7mm~1.6mm;1.6mm~4.0mm; 4.0~8.0mm;Annealing for steel wire 20lines ,30lines…

Online Annealing Furnace type:

• The whole furnace adopts countercurrent open fire heating type, each section controls temperature and adjusts atmosphere separately. Using gas heating technology, the main characteristics of the furnace type are: open flame heating, oxygen and oxygen combustion and control.

• Total thermal risk control technology can maximize gas energy consumption and reduce production and operating costs compared to other furnace types. Temperature control, wind and gas ratio coefficient, safety failure, etc. are fully controlled by the program.

• The whole furnace is composed of multiple furnace bodies, and the wire inlet is respectively equipped with a heating section, a heating section, a heating section, a heating section and a heating section. Each section of heating is relatively independent and influences each other.

• The front and rear steel wire inlet and outlet of the furnace are equipped with electric switch furnace doors, easy to operate.

• Smoke exhaust system: the smoke is discharged from the inlet wire, through the air heat exchanger, furnace pressure electric regulating valve, through the smoke pipe into the steel chimney natural emission.

Furnace lining structure

The furnace body adopts mullite refractory brick to strengthen the heat preservation of the furnace and improve the thermal stability during production.

External walls are made of kom-mullite poly brick + thermal insulation board

Gas supply main and combustion safety system

The gas supply main pipe is composed of electric regulating valve and solenoid valve.

Automatic control system and instrument detection device

• The gas pressure regulator is set in front of the furnace to ensure the stable operation of the control system.

• All hot air combustion system and a factor (air fuel ratio) real-time control.

Electrical configuration:

Heat treatment computer control system includes Germany Siemens PLC and Taiwan Advantech brand industrial computer IPC.

the lower computer is Germany Siemens PLC.

![]()

| No. | Item | Specification |

| 1 | Type of fuel | Natural gas |

| 2 | Electrical Power | Three-phase five-wire system |

| 3 | Length furnace | 27.5m |

| 4 | Net width inside furnace | 1.39m |

| 5 | Number of heating sections | 4 |

| 6 | Heating power | 95 ×104×4.18KJ/h |

| 7 | Max Temperature | 950℃ |

| 8 | Heating Method | Side Heating |

| 9 | Number of burners | 28 |

| 10 | Approve lines | 40 |

| 11 | Furnace temperature control accuracy | ±3℃ |

| 12 | Waste heat recovery and | High efficiency plug-in |

|

heat exchange device type |

tubular heat exchanger |

Show Online Annealing Furnace:

Show Inner Annealing Furnace Structure:

Related products

-

HUB III Bearing Unit Assembly Line

Contact Us● HIGH EFFICIENCY / QUICK CHANGEOVER / FULL AUTOMATION / DATA TRACEABILITY

● LEADING TECHNOLOGY / SIMPLE OPERATION -

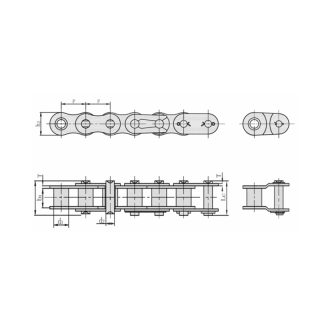

Short pitch precision roller chains(A series)

Contact UsShort pitch precision roller chain, also known as A series roller chain, is a type of roller chain characterized by small pitch and precise construction. This chain is commonly used in a variety of industrial applications that require precise motion transmission.

-

Premium Automotive Injection Mould – Advanced Technology for Auto Component Production

Contact UsPlace of Origin:Shenzhen,China

Model Number:OEM/ODM

Product:Plastic Injection Mould

Application:Automotive Equipment

Mould material:H13/P20/NAK80/S136/2738/2316/S7/1.2344

Mould Life:250000-300000shots

Surface treatment:Polishing

Certification:ISO9001 ISO13485 IATF16949 -

OIL SPRAY MACHINE

Contact UsGuangdong Baimai Equipment Technology Company was established in Dongguan, the city is located in China’s global bay area “Guangdong-Hong Kong-Macao Greater Bay Area”, known for its manufacturing.

Reviews

There are no reviews yet.