Automatic Inserting Pulling Force Tester(KZ1220S)

In addition to fulfilling the basic functions of insertion and extraction force testing, this machine’s testing software also features the ability to export single or multiple raw test data

Automatic Inserting Pulling Force Tester(KZ1220S)

4.1 Machine Features

● Test conditions are set via computer screen and can be saved. Settings can

be selected from drop-down menus or directly entered. (Including test type,

direction of motion, load measurement range, stroke measurement range, stroke

origin position, stroke origin detection, measurement speed, total number of

measurements, pause time, waiting position per cycle, and number of air

compression cycles). Connector single-hole insertion/removal test.

● Can save and print graphs (load-stroke curve, load decay life curve,

inspection report).

● Overload protection function for load cells, ensuring no damage to the load

cells.

● Simultaneously displays load-stroke curve and life curve.

● Automatic zero-point load detection, with the ability to set the origin

detection load value.

● Load unit display: N, lb, gf, kgf, freely switchable.

● Can be used with multiple load cells simultaneously. (2kgf, 5kgf, 20kgf,

50kgf, 100kgf, 200kgf, 500kgf) (Optional).

● The machine adopts a high-rigidity structural design with a servo motor,

ensuring accuracy even under prolonged use. Suitable for general tension and

compression tests, and insertion/extraction force life tests.

● Over-specification stop (During life testing, the machine automatically

stops when test data exceeds the set upper and lower limits).

● Measurement items: Maximum load value, peak value, valley value, load value

at stroke, stroke value at load, insertion point resistance value (optional),

resistance value at load or stroke.

● Equipped with dedicated MES software, supporting MES integration.

4.2 Standard Fixture

4.3 Software Introduction

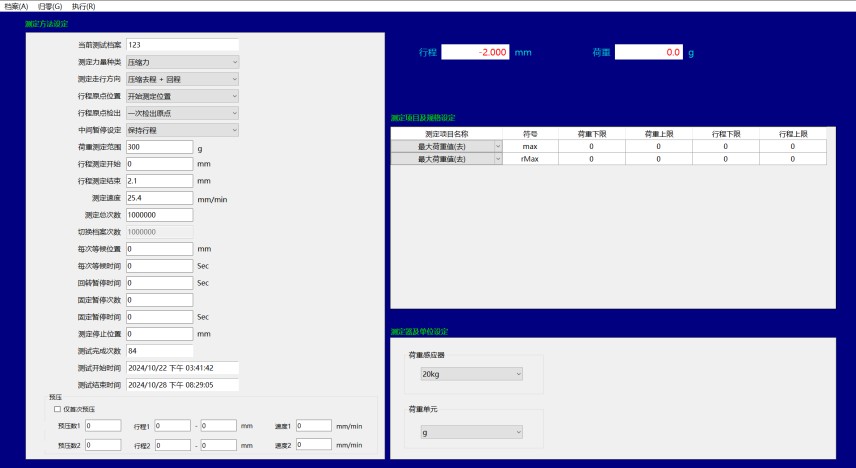

4.3.1 Parameter Interface

● Directly input test items and test methods (end position, test speed,

number of tests, etc.)

● Test conditions can be flexibly input.

● Test results can be added infinitely and recalculated.

● Test items include

maximum and minimum load values, interval values, average values, and values

at specific locations.

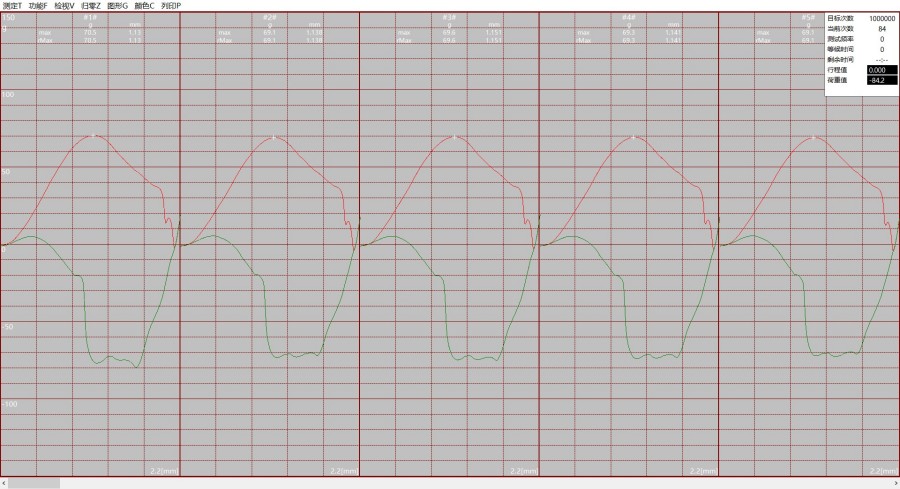

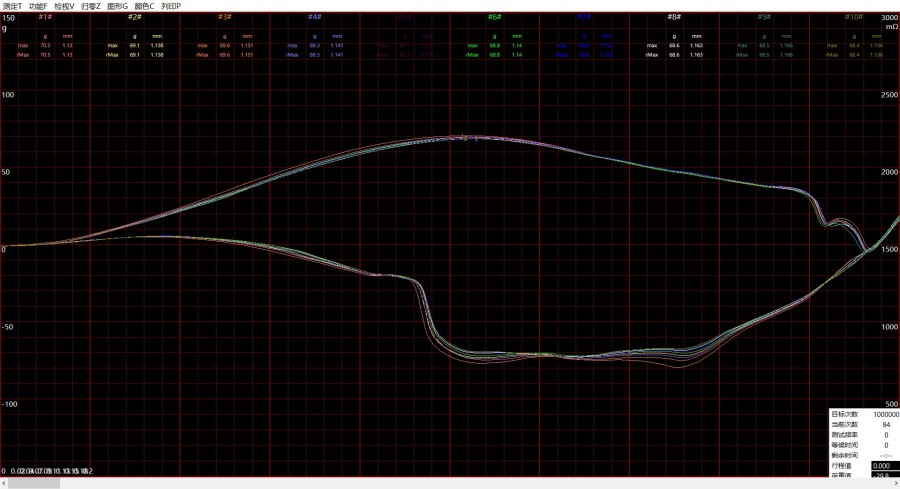

4.3.2 Insertion/Removal Load-Stroke Curve

● Directly displays and stores the displacement and force changes for each

test. (X-axis represents stroke, Y-axis represents force)

● Each measurement graph can be traced using a crosshair cursor to interpret

the load and stroke values corresponding to each measurement point, with a

minimum resolution of 0.01mm (0.001mm).

● Curves are automatically stored by the computer, can be zoomed in and out

at any time, and multiple curves can be displayed on a single sheet.

● Scroll bar-style curve display allows for browsing of curves.

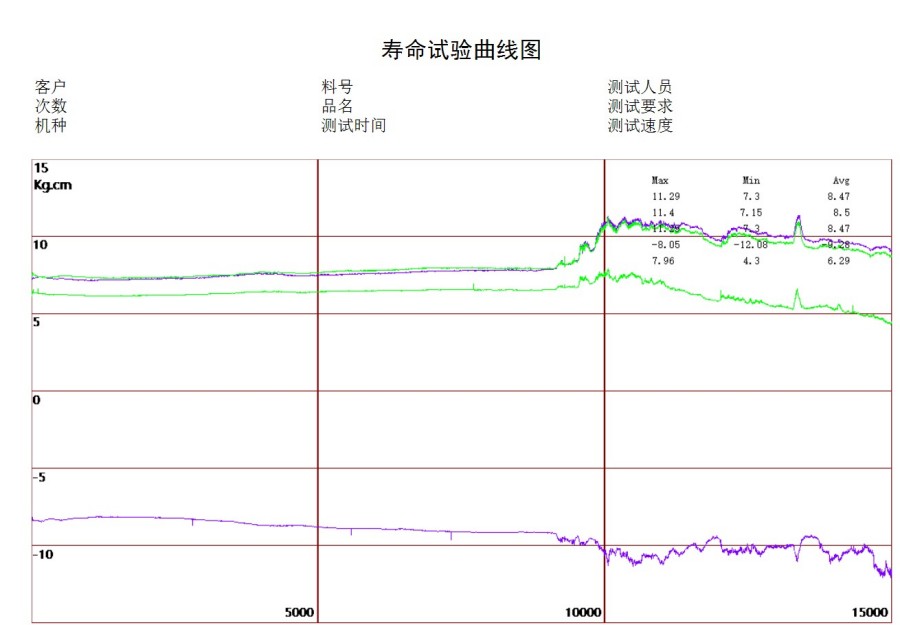

4.3.3 Lifetime Curve

● Report header content can be modified at any time.

● The report can display the maximum, minimum, and average values for each

curve.

● The report can display the upper and lower limit specification lines for

the test.

● Multiple lifetime curves can be displayed simultaneously.

● Simultaneously displays "Load-Stroke Curve" and "Lifetime Curve"

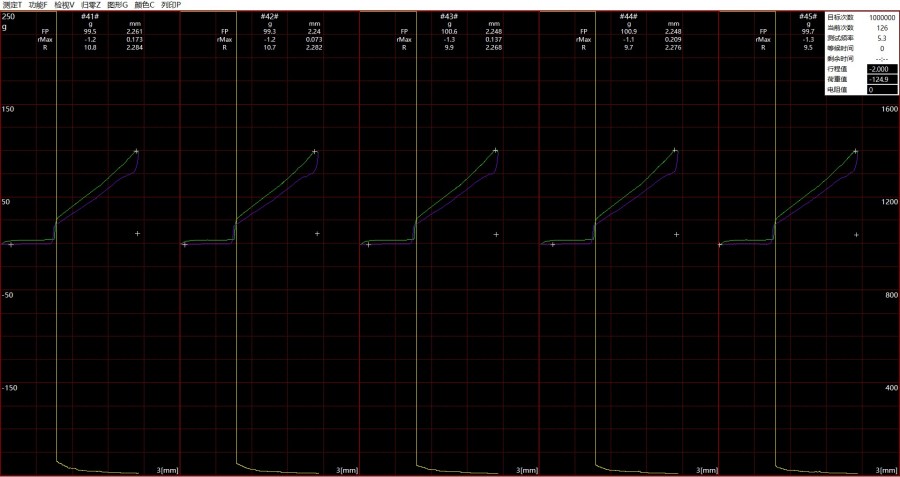

4.3.4 Insertion/Extraction Force and Impedance Curve

● Impedance Function (Four-Wire Dynamic Impedance)

● Report header content can be modified at any time

● Displays the maximum and minimum values of each curve.

4.3.5 Overlapping Curves

● To clearly see the stability of the tested product and the changes in the

product curves, we can compare load-stroke curves from different tests.

● By selecting the number of times the product was tested and setting

different colors, all curves for the selected number can be overlaid together

for easy viewing and analysis.

● Up to 32 sets of curves can be overlaid.

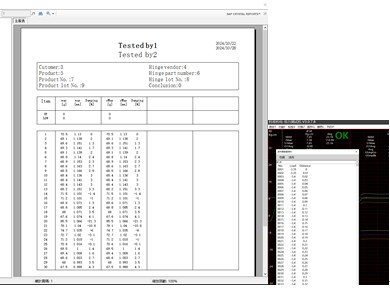

4.3.6 Test Reports

● Test reports are automatically generated (A4 size) and can be exported

(e.g., to Excel) or directly exported via the network.

● Report header content can be modified at will.

● Automatically calculates: maximum value, minimum value, average value,

attenuation rate, etc.

● You can enter the upper and lower limits of the test.

|

Model |

MODEL:KZ1220S |

|

Minimum display range |

0.01mm |

|

Machine column spacing |

270mm |

|

Test load type |

2kgf, 5kgf, 20kgf, 50kgf, 100kgf, 200kgf, 500kgf (optional) |

|

Minimum load |

0.1gf、 1gf、10gf、10gf、10gf、10gf、100gf |

|

Load accuracy |

0.2%FS |

|

Maximum test trip |

200mm |

|

Test speed range |

1-400mm/min |

|

Gear |

Ball screw |

|

Drive motor |

servo motor |

|

Dimensions |

410 (W)×260(D)×1200(H)mm |

|

Machine weight |

Approx. 75KG |

Related products

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m -

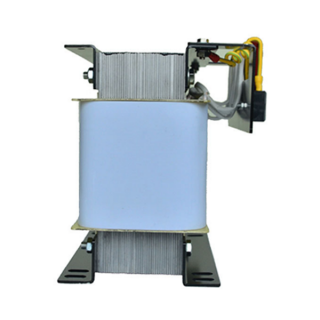

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

-

RO EDI

Contact UsOrisun group is specialize in supplying one stop solutions for whole manufacture chain. developing and manufacturing reverse osmosis water treatment for over 20 years.Our equipment is widely used in pharmacy industry , food and beverage industry , cosmetic industry , chemical industry, etc.As a leading provider of water treatment solutions ,our mission is to supply clean , healthy and safe water for all over the world.

Reviews

There are no reviews yet.