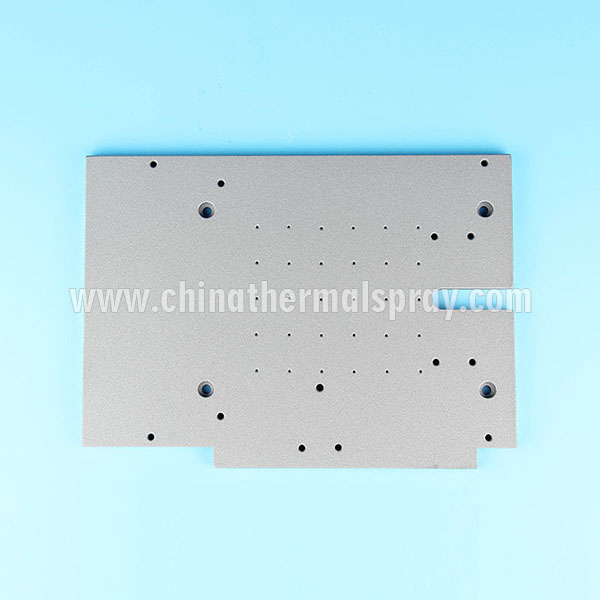

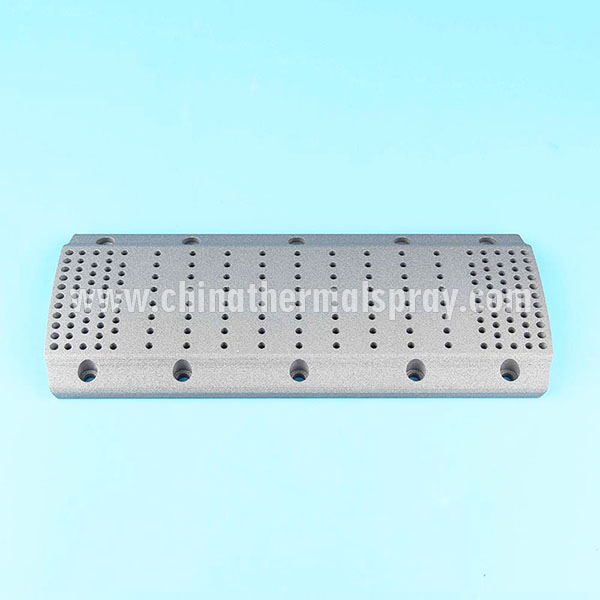

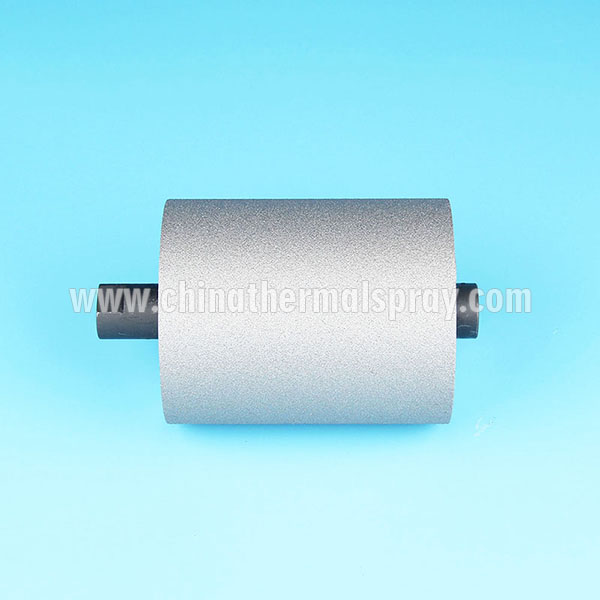

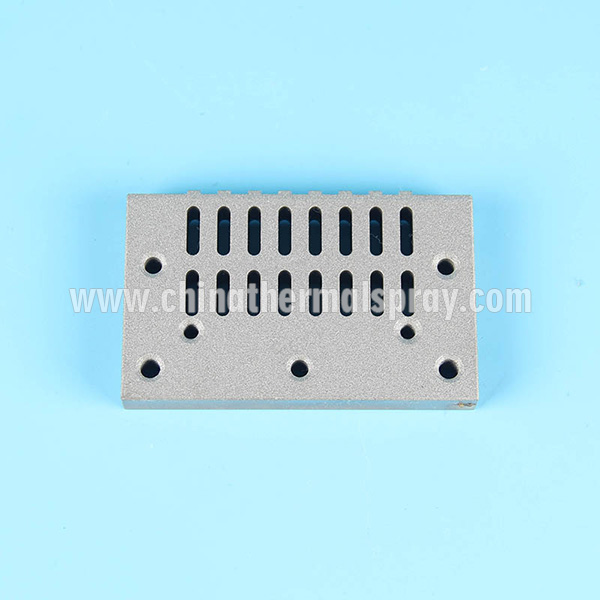

Anti-Sticking Wear-Resistant Coating

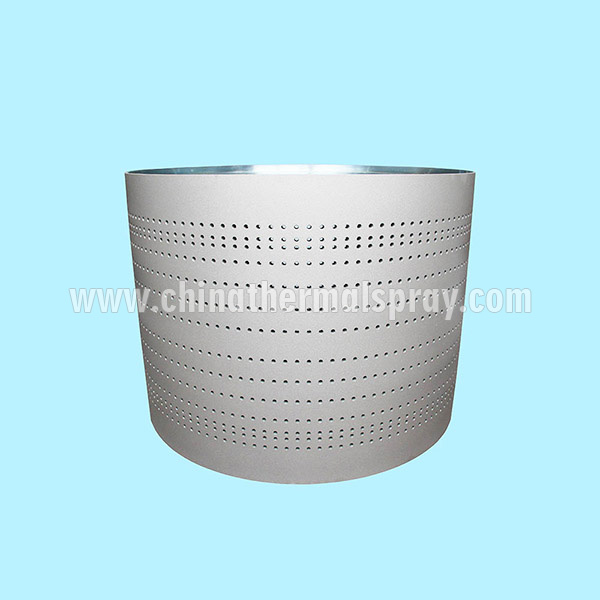

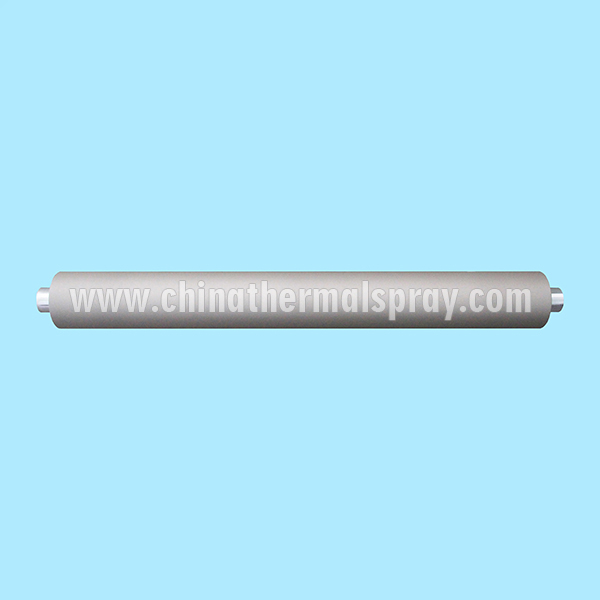

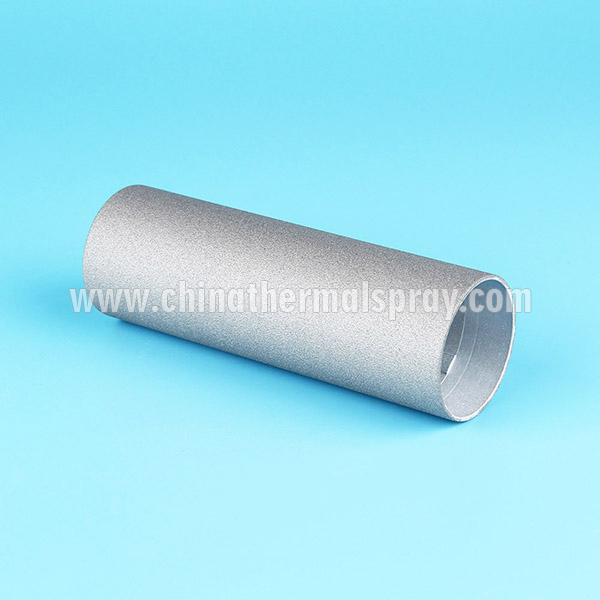

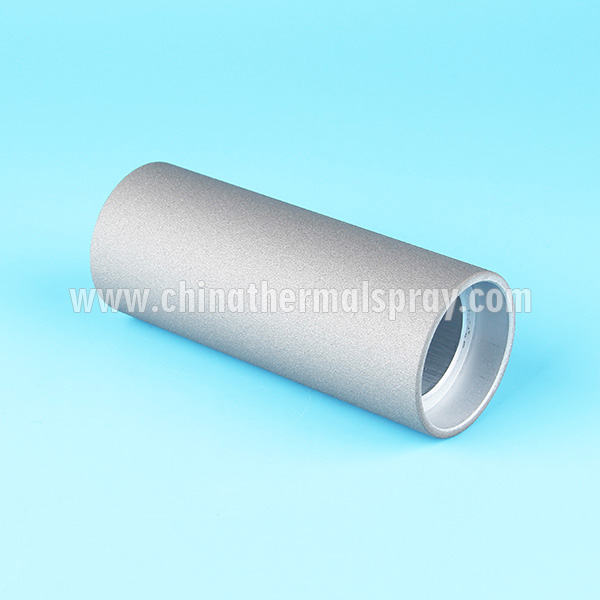

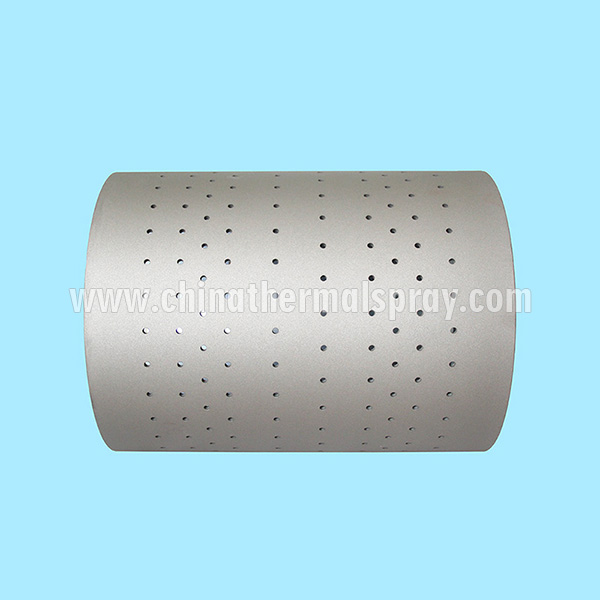

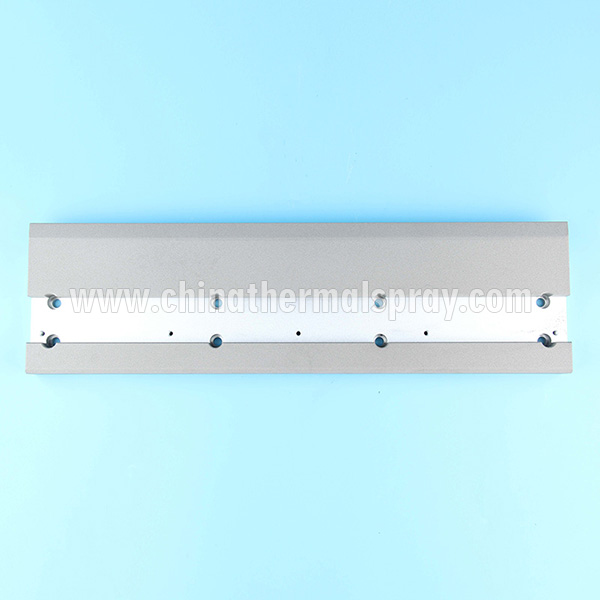

Mainly used in coating machines, printing machines, printing and dyeing machines, tape production machinery, diaper production machinery and other transmission rollers.

Anti-Sticking Wear-Resistant Coating-Mainly used in coating machines, printing machines, printing and dyeing machines, tape production machinery, diaper production machinery and other transmission rollers. Usually, some drive rollers of these equipments need to contact the glued surface, printing surface or printing surface, and the undried printing surface and printing surface are easy to contaminate the roller and affect the surface pattern of the product.

Stripping strength of traditional anti-sticking coating "Teflon" is too strong for hot melt adhesive. That is the anti-sticking performance and wear-resistance is not too good which led anti-sticking performance will lose effect in a short time. It will lead to low production efficiency, short maintenance cycle and high cost.

The invention patent independently researched and developed by our company "thermal spray anti-stick wear-resistant coating" adopts plasma thermal spray technology, uses nickel-based alloy dispersion bond polymer anti-stick material, and uses bionics "Lotus leaf effect", the coating has extremely low adhesive peeling force and excellent wear resistance, and the overall performance is dozens of times higher than that of Teflon coating, reaching the national leading level in this field.

Related products

-

Air conditioner ducted Powerful units with high cooling and heating capacity K48UFR-725P

Contact Us● Powerful units with high cooling and heating capacity

● Lightweight design, intelligent design

● Longer battery life, meeting the need for a full night’s sleep

● Energy saving/lightweight/quiet

● Split structure, bottom mounted

● Energy saving and low consumption, quality assurance

● The company has passed the automotive industry IATF16949 certification -

Ceiling Mounted Cassette type AC for RV ——K48UC-735TPG

Contact Us● The cooling capacity reaches up to 3500w, providing powerful cooling performance.It can achieve a maximum temperature decrease of 13′ within 30 minutes of operation

● The overall perceived noise level on the indoor side can be as low as 40dB or less

● The outdoor unit saves space underneath the vehicle,resulting in improved ground clearance and better maneu verability

● Using a dual-rotor DC variable frequency compressor, the operation is smoother,with less vibration and lower noise

● Variable frequency control technology, more energy-efficient

● DC input, no need for inversion, more efficient electricity usage

● Dual-sided drainage structure on the indoor unit allows for smooth drainage evenwhen parked on a slope

● Designed to meet automotive-grade standards, it fulfills the requirement of4.5G vibration acceleration and can be used during both driving and parking

● The outdoor unit is waterproof up to IPX7, making it resistant to waterimmersion and washing -

Portable 12V&24V Jump Starter with Lithium lron Phosphate

Contact UsJump Starter featuring advanced lithium iron phosphate technology.

-

Sungrow String Inverter SG 6.0 RS

Contact UsSuitable for 50Hz/60Hz grid, could be used in Asia, Africa,South America,Australia and Europe. Available for hand installation, no need for liftingmachinery assistance.

Reviews

There are no reviews yet.