DYTSS Series Two-shaft Shredder

This series of two-shaft shredder features low noise, low energy consumption and high output. It reflects the superiority of low speed and large torque cutting design. This series of shredders is particularly suitable for the crushing of large-sized plastic materials. After being shredded, the bulk density of the material can be increased, thereby reducing transportation costs. In addition, the material can be further processed after shredding, such as material separation, washing and pelletizing etc.

Suzhou Jwell Machinery Co., Ltd.is an important development strategic center

and manufacturing base of Jinwei Machinery. It is located in Chengxiang

Industrial Park, Taicang, Suzhou, and is 30 minutes' drive from Shanghai

Hongqiao Airport. It covers an area of 20 hectares, with an indoor area of

120000 square meters. It is equipped with advanced CNC machining base for parts

and standard assembly workshop. With more than 1000 employees, it has a

high-quality design and development team and an experienced team of mechanical

and electrical commissioning engineers.

The company focuses on plastic pipe and sheet film extrusion equipment

manufacturing and various professional technical services, and carefully

manufactures plastic extrusion equipment that meets the needs of global users,

of which foreign trade exports account for more than 75%. Strict design, strict

standardized manufacturing process and perfect after-sales service guarantee

system provide users with efficient, energy-saving and high-quality production

line equipment and considerate services.

Contact whatsapp: 138 1703 9977 / 139 1685 8896 / 139 1887 6278 / 134 7257 0215 / 158 0622 6900

Email: salbn@jwell.cn

Summary

This series of two-shaft shredder features low noise, low energy consumption and high output. It reflects the superiority of low speed and large

torque cutting design. This series of shredders is particularly suitable for the crushing of large-sized plastic materials. After being shredded, the

bulk density of the material can be increased, thereby reducing transportation costs. In addition, the material can be further processed after

shredding, such as material separation, washing and pelletizing etc.

| Model | Rotor Dia. | Drive Power | Rotor Blade | Blade Thickness | Crushing Chamber Size Max. |

| DYTSS-32100 | Φ430 | 22×2 | 26 | 40 | 1000×800 |

| DYTSS-40130 | Φ514 | 37×2 | 26 | 50 | 1300×950 |

| DYTSS-50180 | Φ615 | 55×2 | 36 | 50 | 1800×1200 |

Related news of DYTSS Series Two-shaft Shredder

Related products

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Optimizing Cross Cut Saw MAXCUT CS15/15XL

Contact UsMAX CUT CS15/15XL, as a relatively practical type of cross cut saw, it is designed for the bending timber, such as rubber wood.

-

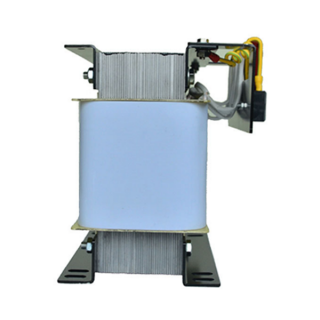

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

Reviews

There are no reviews yet.