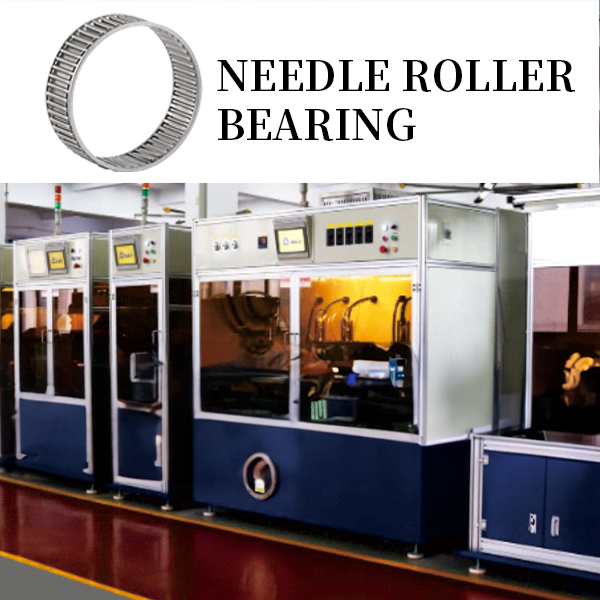

Needle Roller Bearing Assembly Line

● HIGH EFFICIENCY / QUICK CHANGEOVER / FULL AUTOMATION / DATA TRACEABILITY

● LEADING TECHNOLOGY / SIMPLE OPERATION

PRODUCT INTRODUCTION

QUALITY ASSURANCE / LONG WARRANTY / WORRY-FREE OPERATION

-

Product Name: NEEDLE ROLLER BEARING ASSEMBLY LINE

-

Features: WORK PACE OF 10-15S; FLEXIBLE PROCESS COMBINATION; HIGH EFFICIENCY; QUICK CHANGEOVER AND INDEPENDENT RUNNING OF EACH SINGLE MACHINE.

SOME DETAILS

INTELLIGENT / GREEN PRACTITIONER

|

1: INNER & OUTER RING SIZE DETECTION MACHINE HIGH DETECTION PRECISION HIGH DETECTION EFFICIENCY DATA TRACEABILITY |

2: AUTOMATIC CLEANING & DRYING MACHINE HIGH CLEANLINESS EFFICIENT CLEANING DRY THOROUGHLY |

3: LASER MARKING MACHINE ACCURATE MARKING ANTI-DUPLICATE MARKING FLEXIBLE MARKING |

|

|

|

CASE SHOW

High Efficiency / High Precision / High Quality

Related products

-

HUB III Bearing Unit Assembly Line

Contact Us● HIGH EFFICIENCY / QUICK CHANGEOVER / FULL AUTOMATION / DATA TRACEABILITY

● LEADING TECHNOLOGY / SIMPLE OPERATION -

INDUSTRIAL DIRECT GAS FIRED TUNNEL OVEN

Contact UsSuitable for a variety of products baking, there are several choices for the type of transporting belt, you can choose the best type based on the products to be baked.

-

Ribbed Wire Drawing Machine

Contact UsRibbed Wire Drawing Machine , Wire rib drawing machine, Ribbed Wire Rolling Machine suitable for the production of smooth or ribbed low, medium and high carbon steel wire, copper wire…

-

Premium Automotive Injection Mould – Advanced Technology for Auto Component Production

Contact UsPlace of Origin:Shenzhen,China

Model Number:OEM/ODM

Product:Plastic Injection Mould

Application:Automotive Equipment

Mould material:H13/P20/NAK80/S136/2738/2316/S7/1.2344

Mould Life:250000-300000shots

Surface treatment:Polishing

Certification:ISO9001 ISO13485 IATF16949

Reviews

There are no reviews yet.