Ribbed Wire Drawing Machine

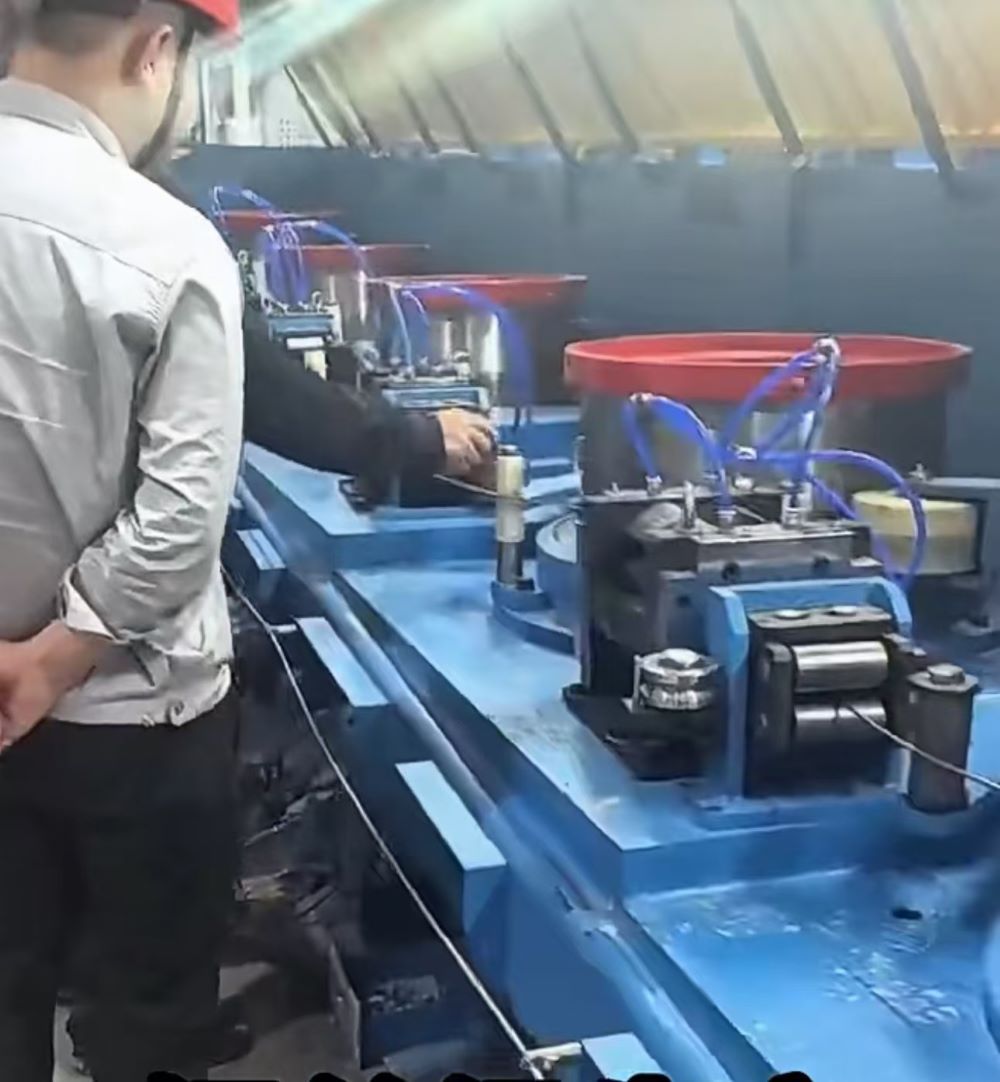

Ribbed Wire Drawing Machine , Wire rib drawing machine, Ribbed Wire Rolling Machine suitable for the production of smooth or ribbed low, medium and high carbon steel wire, copper wire…

Ribbed Wire Drawing Machine

Ribbed Wire Drawing Machine , Wire rib drawing machine, Ribbed Wire Rolling Machine suitable for the production of smooth or ribbed low, medium and high carbon steel wire, copper wire, aluminium and titanium wire, steel and copper cord

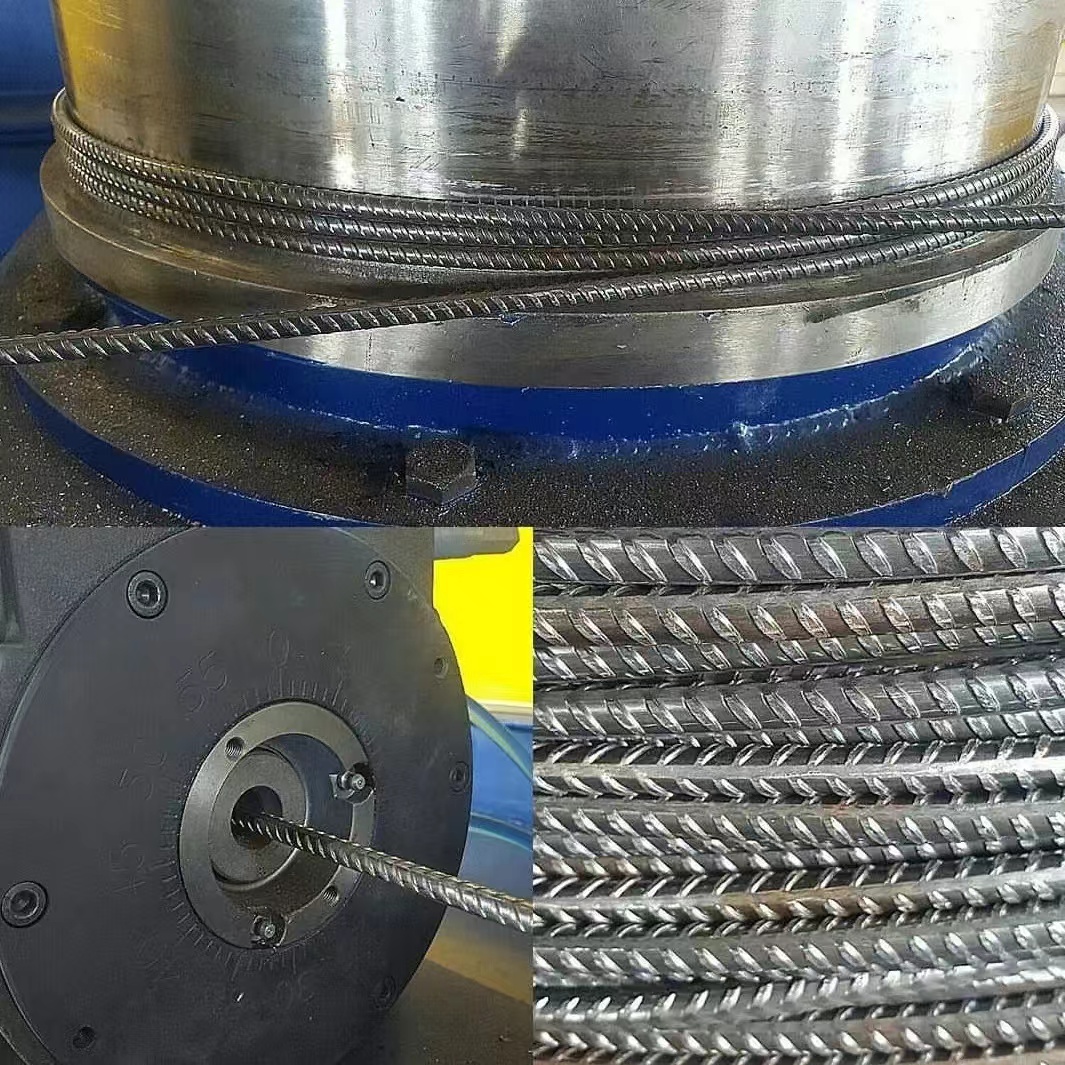

Ribbed Wire, Wire Rib

For wire size: φ2.0mm, φ3.0mm, φ3.5mm, φ4.0mm, φ4.5mm, φ5.0mm, φ5.5mm, φ6.0mm, φ7.0mm, φ8.0mm, φ9.0mm, φ10mm, φ11mm, φ12mm, φ13mm, φ14mm, φ15mm, φ20mm,

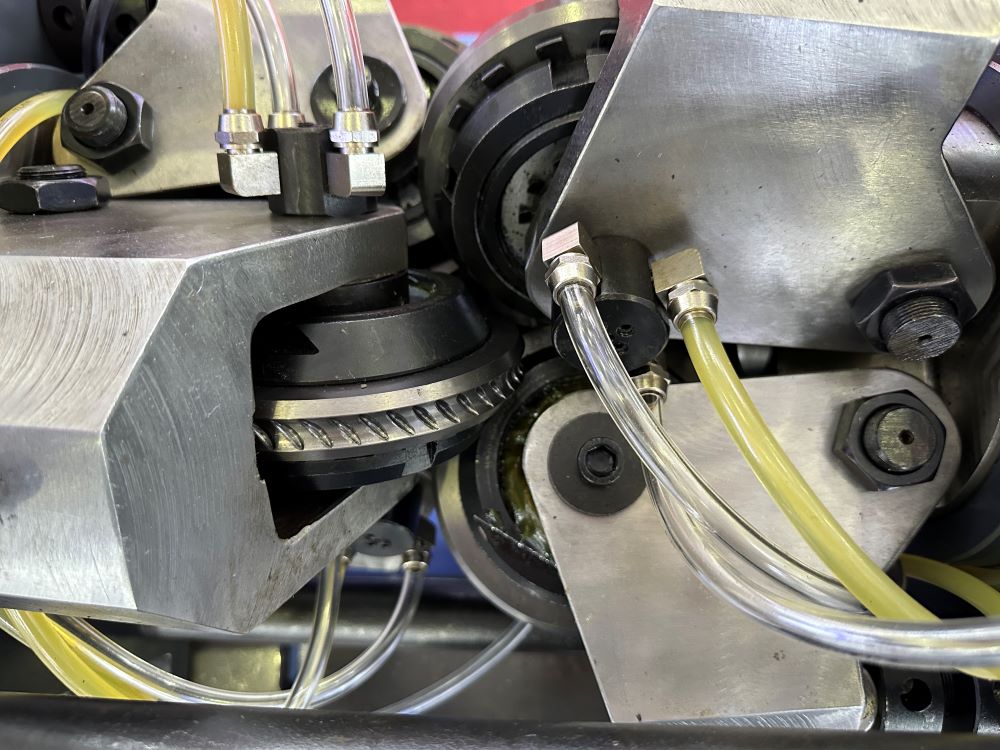

Cassette Rollers Dies Tungsten Carbide Rolls according to any International Standard

φ123mm-φ82mm-15mm/20mm; φ125mm-φ82mm-15mm/20mm;

φ150mm-φ82mm-15mm/20mm; φ150mm-φ90mm-15mm/20mm;

Show Ribbed Wire Drawing Machine,Wire Rib Drawing Machine

Parameter:

| NO | Capstan Dia(mm) | 300 | 400 | 500 | 600 | 800 | 900 | 1000 |

| 1 | Max.Iniet wire dia | 2.0~3.5mm | 3.0~4.2 mm | 5.0~6.5mm | 5.5~7.5 mm | 8.0~10.0mm | 11.0~14.0mm | 14.0~16.0 mm |

| 2 | Min.Outlet wire dia | 0.35mm | 0.75mm | 1.0mm | 1.3mm | 2.4mm | 3.5mm | 4.0mm |

| 3 | Drawing passes | 7~10 | 6~12 | 6~12 | 5~12 | 6~9 | 3~9 | 6~10 |

| 4 | Max speed | 16~25 m/s | 16~25 m/s | 12~16 m/s | 12~16 m/s | 10~12 m/s | 10 m/s | 10 m/s |

| 5 | Main motor power | 7.5~11 KW | 11~15 KW | 22~30 KW | 30~45 KW | 45~75KW | 75~90KW | 90~110KW |

| 6 | Max total wire reduction (%) | 94% | 94% | 94% | 94% | 94% | 94% | 94% |

| 7 | Wire inlet strength | ≤ 550 | ≤ 550 | ≤ 550 | ≤ 550 | ≤ 550 | ≤ 550 | ≤ 550 |

| 8 | Pay-off Type | As customers requirement or according actual demand | ||||||

| 9 | Take-up Type | Collecting in coil and bobbin | ||||||

Show Ribbed Dies for Ribbed Wire Drawing Machine

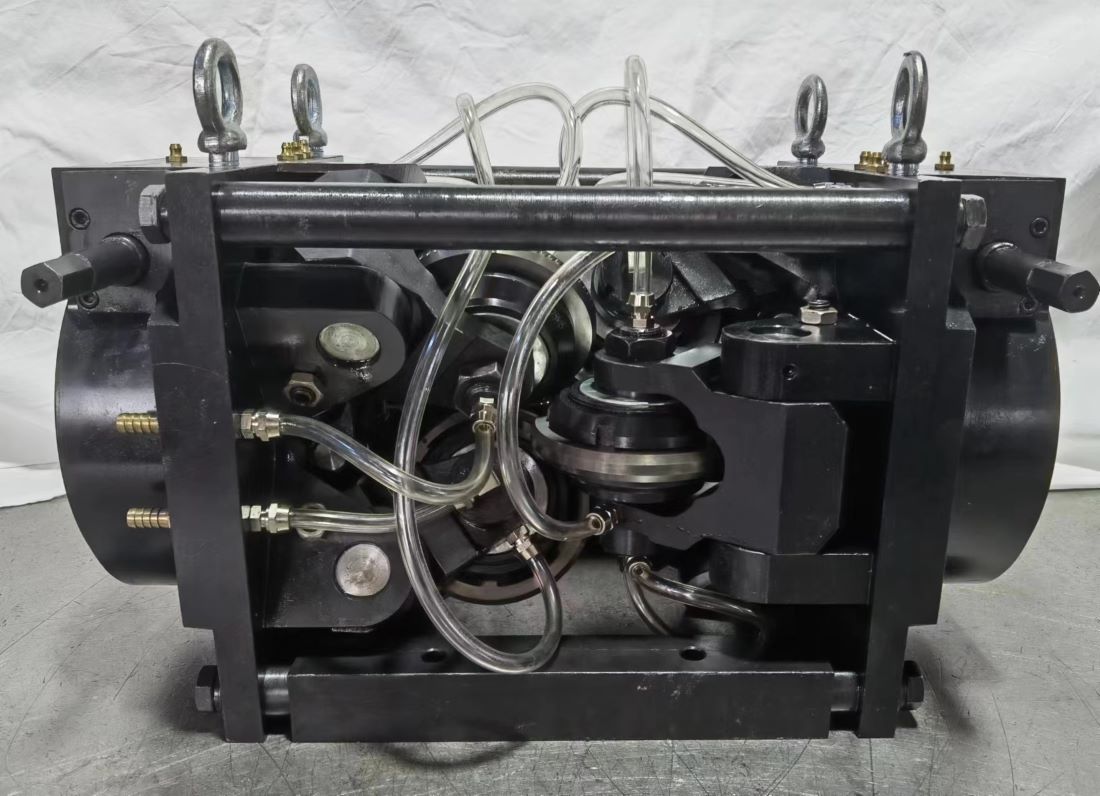

Show Cassette Rollers Dies,Ribbed Dies for Drawing Machine Making

Related News Of Cassette Dies Drawing Machine

Related products

-

Anodic Oxidation Coated Aluminum Alloy Profiles

Contact UsAdvantages/Features: corrosion-resistant, durable, shining and decorative

-

Customized heatsink

Contact UsSurface Finish:Powder Coating, Anodizing, Brushing, Polishing, Electric-plating,powder Coating, Hot Dip Galvanizing, E-coating, Tin Plating,Nickel Plating, Chrome Plating,Decorate, Enamel Coating etc.

-

Electrode-posited copper foil equipment

Contact UsElectrode posited copper foil machine consists of titanium drum, titanium anode tank, titanium anode plate, passivization modules and winding modules.

-

OIL SPRAY MACHINE

Contact UsGuangdong Baimai Equipment Technology Company was established in Dongguan, the city is located in China’s global bay area “Guangdong-Hong Kong-Macao Greater Bay Area”, known for its manufacturing.

Reviews

There are no reviews yet.