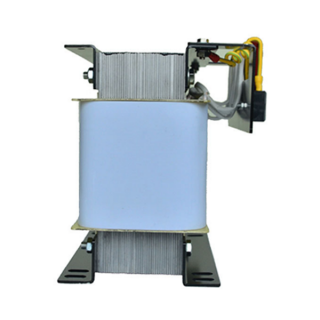

Vertical Iron Roller Rice Whitener Machine

The combined whiteners can reduce elevators for the structure of the downward entering and upward existing.Screw can ensure the truster to largely promote the output.

Characteristic of Vertical Iron Roller Rice Whitener Machine:

◆The combined whiteners can reduce elevators for the structure of the downward entering and upward existing.Screw can ensure the truster to largely promote the output.

◆Spraying and suction combining is efficient to prevent the bran chaff.

◆High output,less broken;Fine milling process with water device have polishing efficiency.

◆Brandname components configuration,durability,safety and reliability.

◆Configuration of beside machine switch,Intelligent adjust indicator and depression meter indicator.According to the predetermined limit on the main motor,electricly control the entering screw is on or off,avoid the milling machine room jam to protect the main motor.

Main technical parameter:

|

Model |

Output |

Power |

Air volume |

Size |

Weight |

||

|

MNLT21 |

4-6t/h |

37-45KW |

Feed roller motor:1.5KW |

Air fan motor motor:2.2KW |

40m³/min |

1430x1390x1920mm |

1310kg |

|

MNLT26B |

7-10t/h |

45-55KW |

Feed roller motor:1.5KW |

Air fan motor motor:2.2KW |

50m³/min |

1560x1470x2150mm |

1770kg |

|

MNLT28A |

9-12t/h |

55-75KW |

Feed roller motor:1.5KW |

Air fan motor motor:2.2KW |

50m³/min |

1560x1470x2250mm |

1850kg |

|

MNLT30 |

10-14t/h |

75-90KW |

Feed roller motor:3.0KW |

Air fan motor motor:2.2KW |

50m³/min |

1880x1590x2330mm |

2280kg |

Related products

-

Waste Tyre Recycling Production Line

Contact UsPresently, waste tire recycling equipment provided by our domestic competitors usually can produce 20-40 meshe rubber powder under normal temperature.

-

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

Reviews

There are no reviews yet.