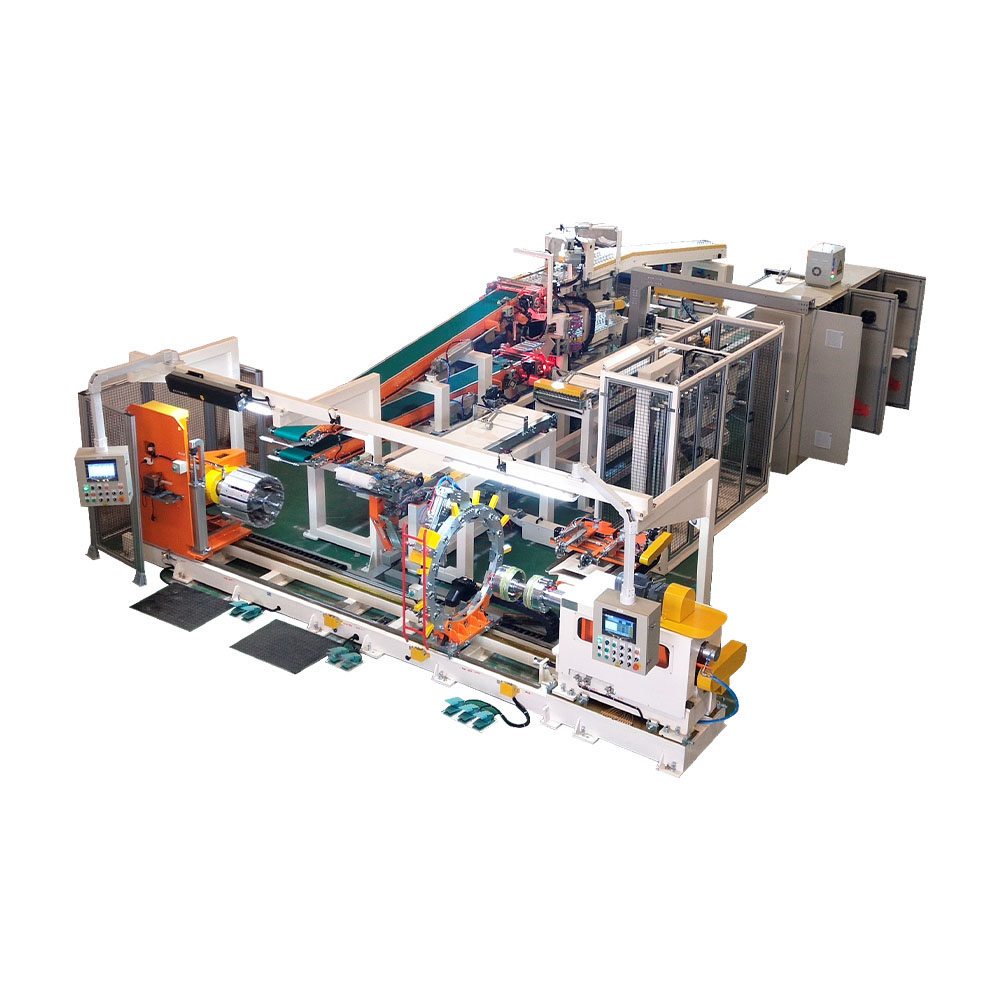

High Precision Second-Stage Tire Building Machine

● Suitable for the production of second-stage HP/UHP/SUV/MT/AT tires ● MITSUBISHI/SIEMENS/AB control systems are optional ● Automatic deviation correction of belt feeding rack, pre-cutting

Product Features:

-

Suitable for the production of second-stage HP/UHP/SUV/MT/AT tires

-

MITSUBISHI/SIEMENS/AB control systems are optional

-

Automatic deviation correction of belt feeding rack, pre-cutting, automatic belt drum (joint detection is optional)

-

Full range of servo for main engine/rear pressure mechanism transmission mechanism, ensuring tire molding quality and efficiency

-

The crown strip adopts displacement sensor and proportional valve to control the tension from 5-50N

-

Belt top and bottom can be selected

-

Various crown strip laying methods

-

Automatic deviation correction of belt CCD camera

-

Ultrasonic cutting of tread, heating of the incision of the head and tail

Equipment Parameters:

|

Item |

Parameters |

|

Tire specifications |

10″~16″ (14″-18″, 17″-21″) |

|

Tire process |

Crown side |

|

Applicable belt drum outer diameter |

φ400~φ580mm |

|

Applicable belt drum width |

350mm |

|

Radial rolling range of combined rollers |

φ390~φ750mm |

|

Axial rolling range of combined rollers |

50~530mm |

|

Clamping range of belt layer transfer ring |

φ390~φ820mm |

|

Width range of two-stage forming drum (expansion and contraction chuck) |

120~600mm |

|

Belt layer width |

70~260mm |

|

Belt layer cutting angle |

18~45° |

|

Belt layer cutting fixed length |

±2mm |

|

Tread width |

100~310mm |

|

Tread ultrasonic cutting angle |

20~35° (angle with horizontal direction) |

|

Single crown strip width |

10~25mm |

|

Crown strip fitting width |

70~270mm |

|

Single tire working efficiency |

<55 seconds (12 inches, one layer of winding method) |

Equipment Accuracy:

|

Item |

Accuracy |

|

Base rail horizontal accuracy |

≤0.05mm/1000mm (≤0.2mm/full length) |

|

Radial runout of the second-stage forming drum main shaft |

≤0.15mm |

|

Coaxiality of the second-stage main machine and the belt transfer ring |

≤0.3mm |

|

Coaxiality of the belt drum and the belt transfer ring |

≤0.25mm |

|

Radial runout of the belt drum main shaft end |

≤0.05mm |

|

Band transfer ring end face (processing reference surface) runout |

±0.2mm |

|

(Measured based on the second-stage forming drum main shaft) |

±0.2mm |

|

Band transfer ring end face (processing reference surface) runout |

≤±0.5° |

|

(Measured based on the belt drum main shaft) |

≤±0.50mm |

|

Laminating drum positioning stop accuracy |

≤0.6mm |

|

Forming head width adjustment positioning error |

≤1mm |

|

Line marking light line width |

18~45° |

|

Line marking light position accuracy |

Butt joint 0~-1 steel wire |

|

Belt steel wire angle |

±1mm |

|

Belt joint form |

20°~35° |

|

Belt laminating centering |

Bevel joint |

|

Tread cutting slope |

±1mm |

|

Tread joint form |

±2mm |

|

Tread laminating centering accuracy |

0~1mm (flat laying method) |

|

Tread fixed length accuracy |

±1mm |

|

Crown band winding gap deviation |

±10mm |

|

Crown band winding total width |

±0.1mm |

|

Crown band head and tail joint spacing |

±1mm |

Related products

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

VMC 500 CNC Vertical Machining Center

Contact UsThe machine is suitable for communication, medical equipment, power tools, 3C products processing,etc.Three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

Reviews

There are no reviews yet.