Ram Type CNC540 CNC650 CNC850 CNC1060 CNC EDM Machine

Adaptive discharge machining process.

High speed lifting and lifting tool height control.

Spindle fixed point control, discharge gap detection

Groove oil level control.

Fire-proof control, Automatic alarm device.

Carbon deposit prevention function

Automatic measurement.

Precise edge and plane machining

Finish the servo system of

X Y Z, Panasonic AC servo motor.

X Y Z, resolution 0.4um, Minimum drive unit 1um..

Stainless steel edge for wear resistant.

Main Features:

Adaptive discharge machining process.

High speed lifting and lifting tool height control.

Spindle fixed point control, discharge gap detection

Groove oil level control.

Fire-proof control, Automatic alarm device.

Carbon deposit prevention function

Automatic measurement.

Precise edge and plane machining

Finish the servo system of

X Y Z, Panasonic AC servo motor.

X Y Z, resolution 0.4um, Minimum drive unit 1um..

Stainless steel edge for wear resistant.

Discharge system:

Touch screen 15“ TFT-LCD.

USB for data input and output.

Special processing circuit for cemented carbide.

AUTO processing function unit.

Automatic positioning function unit.

High speed and precision machining system.

Automatic Arc cleaning circuit.

Bulit-in database system.

CNC instruction, support G code, ISO code.

With memory and Reset after power off.

Error message indication function.

| Model | Unit | CNC540 | CNC650 | CNC850 | CNC1060 | |

| Worktable size (length×width) | mm | 850×450 | 900*550 | 1150×650 | 1250×800 | |

| X/Y/Z travel | X-axis | mm | 500 | 650 | 800 | 1000 |

| Y-axis | mm | 400 | 420 | 500 | 600 | |

| Z-axis | mm | 300 | 350 | 400 | 450 | |

| Oil groove inside size | mm | 1350×860×500 | 1650*900*500 | 1800×1150×600 | 2000×1300×700 | |

| Maximum load of electrode | kg | 50 | 100 | 120 | 150 | |

| Max.load on table | kg | 800 | 2000 | 3000 | 3500 | |

| Distance from electrode plate to working table | mm | 690-990 | 460-750 | 480-880 | 550-1000 | |

| Max. Processing speed | mm3/min | ≥500mm3/min(graphite-stell);≥400mm3/min(Cu-steel) | ||||

| Min. electrode consumption | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ||

| Best Roughness, Ra | Ra | Ra 0.1-0.2 | ||||

| Maximum working current | A | 50 | 50 | 50 | 50 | |

| Total input power | KVA | 10 | 10 | 10 | 10 | |

| Input power | V | 220/380/415 | 220/380/415 | 220/380/415 | 220/380/415 | |

Company & Workshops

BOFENG Machinery is a group with 4 factories. BOFENG has about 60000 square

meter work shop.

Production Equipments

The main parts of our machines are processed by cnc machine. We have gantry

type cnc milling machine, cnc vertical machining center, gantry type cnc

grinding machine, cnc laser cutting machine, cnc bending machine, cnc shearing

machine.

Test & Inspection

All machines will be tested before shipment.

Package & Delivery

Related products

-

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

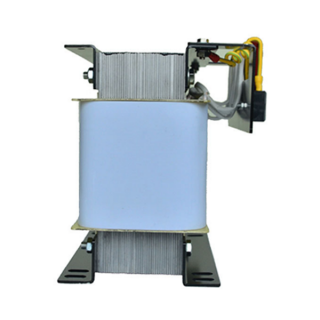

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

-

Capacity 1258ML Hot Filling Suitable For Krones Machine

Contact UsBottle Volume: 1258ml

Bottle Type: hot-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.