Inverted Vertical Wire Drawing Machine

Inverted wire drawing machine is my company introduced Italy advanced technology and designed a large plate heavy wire, large diameter drawing special equipment, easy to operate, reliable, high safety

Inverted wire drawing,Inverted Vertical wire drawing machine

. Low/High Carbon Steel Wire,Fastener,Nut, Screw,Bolt Wire Drawing Machine

– Suitable for materials such as: SAE1010, SAE1018, EN8D, EN19, EN24, 10B21, 15B25, 15B41, 10B35, 1541, etc.

– Used for applications like Fatener, Nut, Screw ,Bolt Wire, Building Wire,Spring wire, Mattress wire,.

Specifiaction:

Inverted wire drawing machine is my company introduced Italy advanced technology and designed a large plate heavy wire, large diameter drawing special equipment, easy to operate, reliable, high safety. Used for metal products, bolt wire, large diameter wire drawing industry.

Inverted wire drawing machine is a non-sliding way to pull high and low carbon steel wire, stainless steel wire, shaped steel wire, alloy wire, suitable for standard parts industry, supermarket shelf manufacturing industry steel wire processing enterprises.

Machine features: The transmission system adopts a strong V-belt combination hard gear reducer; pressure wheel; Down disk independent power and adjustable coil diameter AC frequency conversion speed regulation, easy operation, safe and reliable, energy saving more than 30%. Note: Drum diameter can be customized according to user requirements.

![]()

LD1200, LD1400 the above wire size 20mm: Uncolier wire feeder + Wire top pointing machine (cutting) + inverted wire drawing machine production line,

1. The wire transmission adopts programmable frequency control, which makes the stability of connecting with the wire drawing machine extremely high. For the safe production of the equipment, a number of safety protection devices are designed to make the equipment more stable operation, more safe and reliable. The wire feeding process is fully automatic and requires no manual operation.

2. Cutting mechanism: the transmission is controlled by hydraulic pressure, the operation is simple and flexible, and the cutting process is fully automated.

3. The control of the inverted wire drawing machine is a safe operation mode, which can immediately stop the emergency stop, disorderly line, broken line and electrical faults. The brake system is safe and reliable, easy and flexible, and the whole line operation process is more convenient and reliable

Parameter:

| NO | Capstan Dia(mm) | 700 | 800 | 1000 | 1200 | 1400 |

| 1 | Max.Iniet wire dia | 2.0~3.5mm | 3.0~4.2 mm | 5.0~5.5 mm | 6.0~6.5 mm | 6.5~7.5mm |

| 2 | Working speed | 60~120 m/min | 40~80 m/min | 40~80 m/min | 15~30 m/min | 10~30 m/min |

| 3 | Main motor power | 22~30KW | 37~45KW | 55~75KW | 75~110KW | 110~132KW |

| 4 | Max collecting wire | 1500KG | 2000 | 2500 | 2500 | 2500 |

| 5 | Wire inlet strength.Mpa | ≤ 1250 | ≤ 1250 | ≤ 1250 | ≤ 1250 | ≤ 1250 |

| 6 | Pay-off Type | As customers requirement or according actual demand | ||||

| 7 | Take-up Type | Collecting in coiler | ||||

Show Inverted wire drawing machine

Related products

-

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

PP PE LDPE HDPE Film Recycled Plastic Washing Machine Recycling Production Line For Sale

Contact UsThe recycling washing line is mainly used to recycle all kinds of plastics, such as film, agricultural film, greenhouse film, woven bags and etc. it can also recycle waste plastic bottles such as HDPE, LDPE, PP, etc. Our output ranges from 300 kg to 2000 kg per hour. Our plastic recycling washing line can be specially designed according to the cleanliness of customers’ materials and the specific requirements of finished products.

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

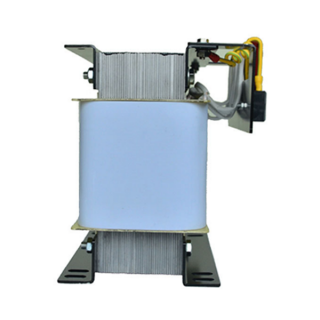

Dry type transformer

Contact UsSafe, fireproof, non-polluting, can be run directly in the load center; using domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability, long service life; low loss, low noise , obvious energy saving effect, maintenance-free

Reviews

There are no reviews yet.