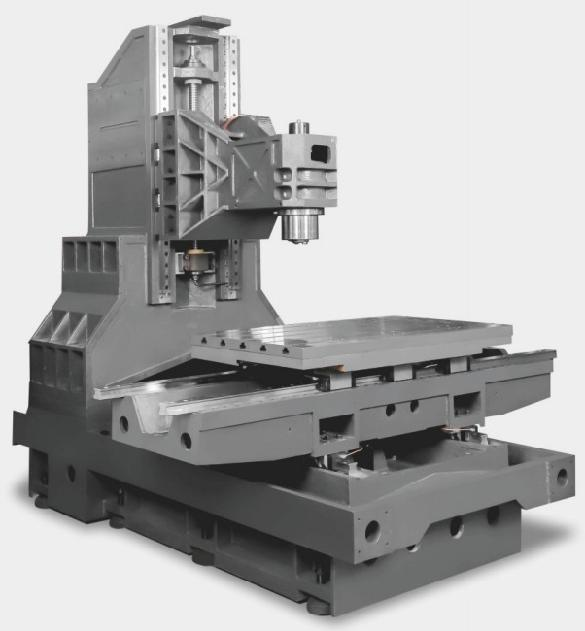

Vertical machining center body

Optional configuration:■Control system: Mitsubishi, Fanuc, Siemens, Shindai■Spindle center water outlet, spindle ring water outlet, high-pressure backwash chip cleaning device (optional)

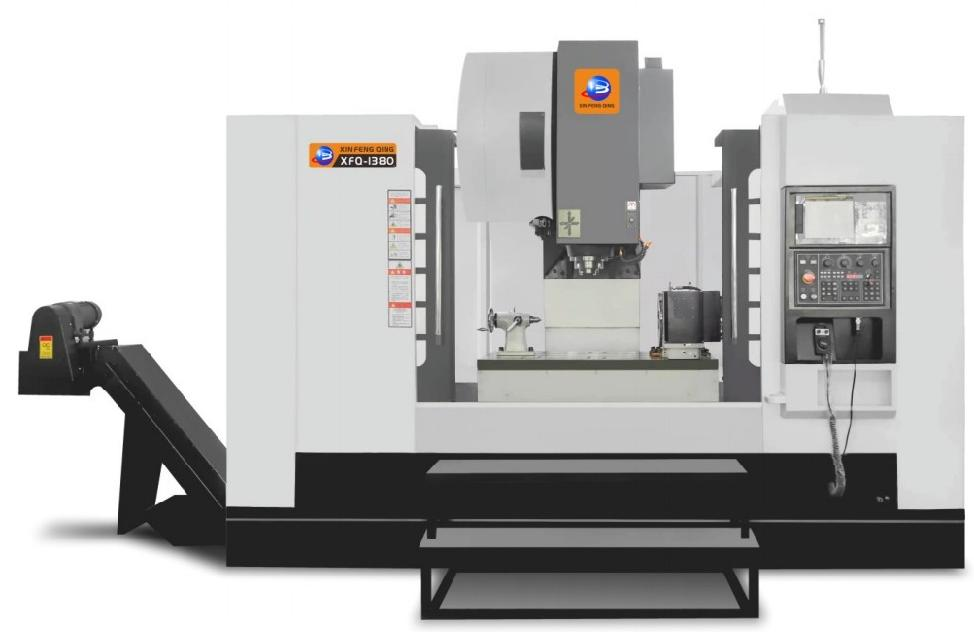

Vertical machining center series

Select Configuration

■ Control System: Mitsubishi, Fanuc, Siemens, New Generation

■ Main spindle center water outlet, main spindle ring water outlet, high rear water debris removal device (optional)

■ Double screw chip conveyor

■ Fourth axis (fifth axis) (optional)

■ Oil mist collector (optional)

Standard configuration

■ Mitsubishi M80 control system/oi mfplus

■ Full face sheet metal

■ Cutting fluid system

■ Power box heat exchanger

■ Automatic power-off

■ Automatic lubrication system

■ Spindle blowing air

■ Steel attack teeth

■ Work light

■ Three color warning light

■ Transformer

■ Foundation screws and school blocks

■ Knife magazine 24T

■ Spindle cooling machine

■ Double screw rear chip

■ Water and fluorine gun device

Excellent properties

1 Made of high-grade cast iron

All major structural castings of the machine tool are made of high-grade Mihanna cast iron high tension material, with stress relief and aging treatment

Demonstrate excellent stability to ensure the optimal precision of the machine that remains unchanged over the long term.

2 Box-shaped symmetric structural design

The herringbone column and base are designed with a box shaped symmetrical structure and reinforced with rationalized cross ribs, which enhances the rigidity of the entire structure

Wells can minimize the degree of deformation during maturation.

3 wide machine base and columns

The combination of a wide machine base and columns ensures the most stable bonding rigidity, which is the foundation of machining accuracy.

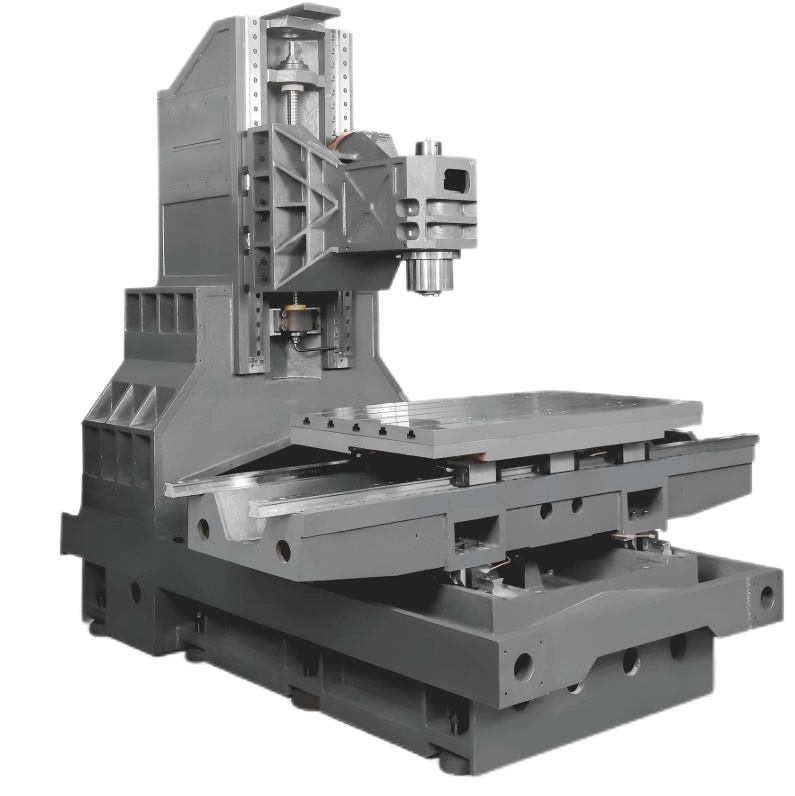

4 Heavy-duty linear guides

Extra wide span and super large track span ensure even load distribution and improve machining accuracy. Jitai is equipped with heavy-duty track with three-axis configuration and preloaded

Processed to eliminate thermal deformation, the high-speed silent screw rain end support is stable and pre tensioned, with excellent rigidity and precision.

5 Perpendicularity inspection in assembly

During the assembly process of the track and screw, the right angle, flatness, and concentricity of the horizontal and vertical planes are all geometrically accurate, presenting precise axial geometric accuracy.

6 Imported high-speed spindle

Imported high-speed spindles have good rigidity, stable high-speed cutting, and significantly improved efficiency.

7 High shifting speed

The three-axis 16-48m/min high-speed displacement can save non machining time, significantly improve machining efficiency, and ensure machining brightness.

Vertical machining center series

Select Configuration

■ Control System: Mitsubishi, Fanuc, Siemens, New Generation

■ Main spindle center water outlet, main spindle ring water outlet, high-pressure flushing chip cleaning device (optional)

■ Double screw chip conveyor

■ Fourth axis (fifth axis) (optional)

■ Oil dew collector (optional)

Standard configuration

■ Mitsubishi M80 control system/oi mfplus

■ Full face sheet metal

■ Cutting fluid system

■ Power box heat exchanger

■ Automatic power-off

■ Automatic lubrication system

■ Spindle oxygen blowing

■ Steel attack teeth

■ Work light

■ Three color warning light

■ Transformer

■ Foundation screws and pads

■ Knife magazine 24T

■ Spindle cooling machine

■ Double screw rear chip

■ Water and oxygen lance device

Heavy-load linear guide-High servo speed! High rigidity! High reliability!

Robust mechanical structure-High- pretension ball screw

Select Configuration

■ Control System: Mitsubishi, Fanuc, Siemens, New Generation

■ Main spindle center water outlet, main spindle ring water outlet, high-pressure flushing chip cleaning device (optional)

■ Double screw chip conveyor

■ Fourth axis (fifth axis) (optional)

■ Oil dew collector (optional)

Standard configuration

■ Mitsubishi M80 control system/oi mfplus

■ Full face sheet metal

■ Cutting fluid system

■ Power box heat exchanger

■ Automatic power-off

■ Automatic lubrication system

■ Spindle blowing air

■ Steel attack teeth

■ Work light

■ Three color warning light

■ Transformer

■ Foundation screws and pads

■ Knife magazine 24T

■ Spindle cooling machine

■ Double screw rear chip

■ Water and air gun devices

|

Machine model |

unit |

XFQ-850 |

XFQ-855 |

XFQ-960 |

XFQ-1160A |

||

|

Processing range |

Workbench travel (X) |

mm |

800 |

800 |

900 |

1100 |

|

|

Saddle travel (Y) |

mm |

500 |

550 |

600 |

600 |

||

|

Head travel (Z) |

mm |

500 |

550 |

600 |

600 |

||

|

Distance from spindle end to table surface |

mm |

150-650 |

150-670 |

100-700 |

120-720 |

||

|

Workbench |

Workbench size |

mm |

1000*500 |

1000*550 |

1000*620 |

1200*600 |

|

|

Workbench load capacity |

KG |

400 |

450 |

600 |

800 |

||

|

T-slot (number*width*distance) |

mm |

18*5*90 |

18*5*90 |

18*6*100 |

18*5*100 |

||

|

Main axis |

Motor power |

kw |

7.5 |

7.5/11 |

11/15 |

11/15 |

|

|

Speed range |

rpm |

10000/12000 |

10000/12000 |

10000/12000 |

10000/12000 |

||

|

Spindle specifications |

BT40 |

BT40 |

BT40 |

BT40(Optional BT50) |

|||

|

Latin specifications |

P40-1/45°(MAS403) |

P40-1/45°(MAS403) |

P40-1/45°(MAS403) |

P40-1/45°(MAS403) |

|||

|

Tool magazine specifications |

Number of standard tool magazines |

24 |

24 |

24 |

24 |

||

|

Tool full diameter/length |

mm |

80/300 |

80/300 |

80/300 |

80/300 |

||

|

Tool Hole Diameter/Length |

mm |

150/300 |

150/300 |

150/300 |

150/300 |

||

|

Maximum tool weight |

kg |

8 |

8 |

8 |

8 |

||

|

Tool change time |

S |

3.5s |

3.5s |

3.5s |

3.5s |

||

|

Guide rail |

X-axis*Number of sliders |

mm |

35*4 |

35*4 |

35*6 |

45*6 |

|

|

Y axis*slider quantity |

mm |

35*4 |

45*4 |

45*4 |

45*4 |

||

|

Z axis*slide quantity |

mm |

35*4 |

45*6 |

45*6 |

45*6 |

||

|

Drive |

Screw rod |

mm |

C3 R4016mm |

C3 R4016mm |

C3 R4012mm |

C3 R4012mm |

|

|

Installation |

Direct connection |

Direct connection |

Direct connection |

Direct connection |

|||

|

speed |

Cutting feed speed range |

mm/min |

10000 |

10000 |

10000 |

10000 |

|

|

Fast moving speed |

mm/min |

48000 |

36000 |

32000 |

32000 |

||

|

Machine tool accuracy |

Positioning accuracy |

mm |

±0.005 |

±0.005 |

±0.005 |

±0.005 |

|

|

Repeatability |

mm |

±0.003 |

±0.003 |

±0.003 |

±0.003 |

||

|

other |

Z axis counterweight |

none |

none |

Yes (Nitrogen weight) |

none |

||

|

CNC system |

Mitsubishi/FANUC |

Mitsubishi/FANUC |

Mitsubishi/FANUC |

Mitsubishi/FANUC |

|||

|

Air source |

flow |

L/min |

500 |

500 |

500 |

500 |

|

|

Air pressure |

Mpa |

0.45–0.7 |

0.45–0.7 |

0.45–0.7 |

0.45–0.7 |

||

|

Total electrical capacity of machine tool |

KVA |

15 |

15 |

20 |

20 |

||

|

Cooling box capacity |

L |

180 |

180 |

200 |

200 |

||

|

Machine tool dimensions |

mm |

2550*2300*2450 |

2650*2280*2656 |

2410*2700*2720 |

3100*2600*2700 |

||

|

Total weight of machine tool |

T |

4500 |

5200 |

6000 |

6000 |

||

|

XF Q – 1160B(Heavy) |

XFQ-1380 |

XFQ-1580 |

XFQ-1890 |

|

|

1100 |

1300 |

1500 |

1800 |

|

|

600 |

800 |

800 |

900 |

|

|

600 |

680 |

680 |

720 |

|

|

100-700 |

140-820 |

140-820 |

115-835 |

|

|

1200*620 |

1400*800 |

1600*800 |

2000*900 |

|

|

800 |

1000 |

1300 |

1600 |

|

|

18*5*112 |

18*7*110 |

18*7*110 |

22*5*165 |

|

|

11/15 |

15/18.5 |

15/18.5 |

18.5/22 |

|

|

10000/12000 |

8000 |

8000 |

8000 |

|

|

BT40(Optional BT50) |

BT50 |

BT50 |

BT50 |

|

|

P40-1/45°(MAS403) |

P40-1/45°(MAS403) |

P40-1/45°(MAS403) |

P40-1/45°(MAS403) |

|

|

24 |

24 |

24 |

24 |

|

|

80/300 |

100/350 |

100/350 |

100/350 |

|

|

150/300 |

200/350 |

200/350 |

200/350 |

|

|

8 |

15 |

15 |

15 |

|

|

3.5s |

5s |

5s |

5s |

|

|

45*6 |

55*6 |

55*6 |

55*6 |

|

|

45*4 |

4*45*8 |

4*45*8 |

4*45*8 |

|

|

45*6 |

55*6 |

55*6 |

Sliding rails |

|

|

C3 R4012mm |

C3 R5010mm |

C3 R5010mm |

C3 R5512mm |

|

|

Direct connection |

Direct connection |

Direct connection |

Direct connection |

|

|

10000 |

8000 |

8000 |

8000 |

|

|

32000 |

24000 |

24000 |

18000*18000*15000 |

|

|

±0.005 |

±0.005 |

±0.005 |

±0.01 |

|

|

±0.003 |

±0.003 |

±0.003 |

±0.008 |

|

|

Yes (Nitrogen weight) |

Yes (Nitrogen weight) |

Yes (Nitrogen weight) |

Yes (Nitrogen weight) |

|

|

Mitsubishi/FANUC |

Mitsubishi/FANUC |

Mitsubishi/FANUC |

Mitsubishi/FANUC |

|

|

500 |

500 |

500 |

500 |

|

|

0.45–0.7 |

0.45–0.7 |

0.45–0.7 |

0.45–0.7 |

|

|

20 |

35 |

35 |

35 |

|

|

200 |

240 |

240 |

240 |

|

|

3100*2700*2700 |

3700*3200*3200 |

4200*2700*2700 |

4200*2700*2700 |

|

|

7500 |

10000 |

12000 |

14000 |

|

Related products

-

DC Rooftop Mounted Vehicle Air Conditioners

Contact Us● Strong air volume, fast cooling

● Lightweight design, intelligent design

● Longer battery life, meeting the need for a full night’s sleep

● Energy saving/lightweight/quiet

● Split structure, rooftop mounted

● Energy saving and low consumption, quality assurance

● The company has passed the automotive industry IATF16949 certification -

Air conditioner ducted Powerful units with high cooling and heating capacity K48UFR-725P

Contact Us● Powerful units with high cooling and heating capacity

● Lightweight design, intelligent design

● Longer battery life, meeting the need for a full night’s sleep

● Energy saving/lightweight/quiet

● Split structure, bottom mounted

● Energy saving and low consumption, quality assurance

● The company has passed the automotive industry IATF16949 certification -

Titanium Alloy Coil

Contact UsWe adhere to the business philosophy of “gathering all the steel in the world and achieving stainless quality”, sincerely looking forward to the joining and cooperation of domestic and foreign merchants, new and old users, and working together to create brilliance

-

PGA Frac Ball

Contact UsPGA fully degradable frac plug ball is a series of frac plug balls developed based on PGA degradable materials to meet the needs of oil fields under various temperatures and working conditions.

Reviews

There are no reviews yet.