UV laser marking machine(MZ-3UV/MZ-5UV/MZ-10UV/MZ-15UV)

The reaction mechanism during laser processing is achieved through photochemical ablation, which relies on laser energy to break the bonds between atoms or molecules, causing them to vaporize or evaporate into small molecules. UV laser marking is characterized by a small focused spot and a wide range of applicable materials, primarily targeting the high-end market for precision processing.

1. Equipment Features

The reaction mechanism during laser processing is achieved through

photochemical ablation, which relies on laser energy to break the bonds between

atoms or molecules, causing them to vaporize or evaporate into small molecules.

UV laser marking is characterized by a small focused spot and a wide range of

applicable materials, primarily targeting the high-end market for precision

processing.

– Excellent beam quality, smaller focused spot, minimal thermal impact, and

delicate marking;

– Most plastic materials can absorb UV laser, compensating for the

insufficient processing capabilities of other lasers;

– High marking speed and efficiency;

2.EquipmentAppearance(Reference)

1) Overall Dimensions: Length 650mm * Width 800mm * Height 1500mm (subject to

actual external dimensions)

2) Chiller Dimensions: Length 580mm * Width 290mm * Height 470mm (subject to

actual external dimensions)

3) Total Weight: 120KG (subject to actual weight)

3. Technical Parameters

|

Item Name |

Technical Parameters |

|

Laser Average Power |

3W@30Hz/5W@30Hz/10W@50Hz |

|

Repetition Rate |

20KHz-200KHZ |

|

Pulse Width |

<15ns |

|

Laser Wavelength |

355nm |

|

Beam Quality M² |

<1.2 |

|

Beam Divergence Angle |

<2mrad |

|

Standard Engraving Range |

110mm*110mm/150mm*150mm/174mm*174mm(optional) |

|

Recommended Engraving Speed Speed |

≤5000mm/s |

|

Minimum Line Width |

0.01mm((depending on material and lens size) |

|

Repetition Accuracy |

±0.05mm |

|

Power Requirements |

220V±22V / 50Hz / 10A |

|

Total Power Consumption |

≤1000W |

|

Cooling Method |

Water Cooling |

4. Hardware Configuration

|

Optical System |

UV laser |

3W/5W/10W |

china |

Integrated UV Laser |

|

UV Galvanometer |

10mm |

china |

Zhibo,Ouye,or Saipusen |

|

|

UV Focusing Lens |

F254 |

china |

Custom |

|

|

Contol System |

Marking Control Card |

EzCAD2 |

china |

BJJCZ |

|

Marking Software |

EzCAD2 |

china |

BJJCZ |

|

|

Industrial Computer |

PC |

china |

/ |

|

|

Display |

19-inch LCD |

china |

Founder or Dell |

|

|

Cooling System |

Constant Temperature Chiller |

CWUL |

china |

Teyu |

5. Sample Images

|

|

|

|

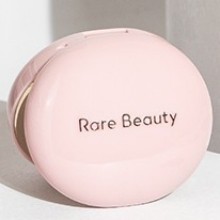

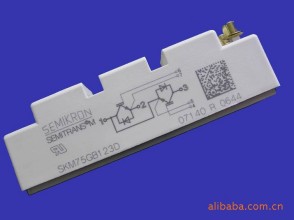

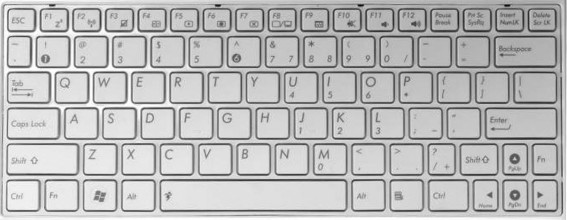

Plastic Logo Marking |

Precision Exterior Part Marking |

Charger Marking |

|

|

|

|

Plastic Shell Marking |

3C Product Marking |

Computer Keyboard Marking |

Samples Subject to Actual Results

6. Working Environment Requirements

1) Ambient temperature should be between 0-35°C, and air conditioning is

required;

2) Humidity should be between 45%-75%. No condensation is allowed, and a

dehumidifier should be installed;

3) Power supply requirements: 220V, 50Hz;

4) Power grid fluctuation: ±5%, and the grounding wire must comply with

international standards. In areas with voltage amplitude exceeding 5%, an

electronic automatic voltage and current stabilizer should be installed;

5) There should be no strong electromagnetic signal interference near the

installation site. Avoid radio transmission stations (or relay stations) in the

surrounding area;

6) Foundation vibration amplitude: recommended to be less than 50 µm;

vibration acceleration: recommended to be less than 0.05g. Avoid having a large

number of stamping or other machine tool equipment nearby;

7) The equipment space must be smoke-free and dust-free. Avoid environments

with severe dust, such as metal polishing or grinding;

8) Strict requirements for the quality of cooling water: purified water,

deionized water, or distilled water must be used. Tap water, mineral water, or

other liquids containing high levels of metal ions or minerals are not

allowed.

Related products

-

MA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment

Contact UsMA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment can process the slitting of the coil with different sizes to small strips for processing various kinds of metal coil materials.

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m -

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line.

Reviews

There are no reviews yet.