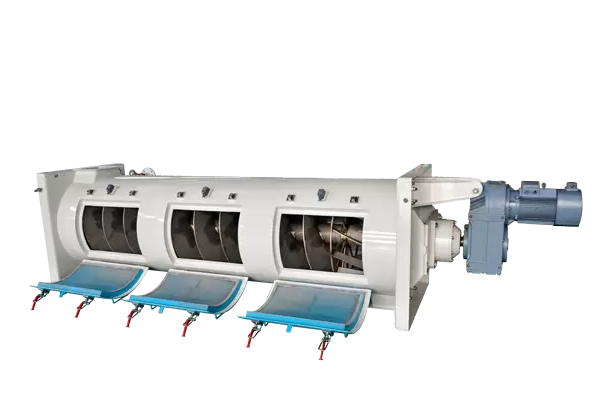

STZB、STZR Retentioner

The equipment is mainly used for conditioning and sterilization which before pelleting, extruding in feed production. When used with other equipment such as feeding and conditioner, it can greatly imp

Device Description

The equipment is mainly used for curing and sterilization before granulation and bulking in feed production process. By combining with other equipment such as feeding and tempering, the curing degree of materials can be greatly improved;

The external steam jacket or heat armour is heated,and the internal spiral blade conveys materials, which can ensure first-in first-out and reduce residue and cross-contamination.

Hot nail heating temperature rise fast, high thermal efficiency.

Driven by a shaft-mounted reducer,the operation is stable,and the special screed structure ensures the stable current of the pellet mill.

Equipped with variable frequency motor, conditioning time extends up to 3 minutes, can make the material fully cooked, optimize the pelleting process, and improve the capacity which can be increased by 10-15%.

The conditioning temperature can reach 85-100℃(adjustable), which can improve water resistance and effectively kill African swine fever virus and Salmonella.

Special homogenizing and dispersing mechanism, stable and uniform discharge

Related products

-

RO EDI

Contact UsOrisun group is specialize in supplying one stop solutions for whole manufacture chain. developing and manufacturing reverse osmosis water treatment for over 20 years.Our equipment is widely used in pharmacy industry , food and beverage industry , cosmetic industry , chemical industry, etc.As a leading provider of water treatment solutions ,our mission is to supply clean , healthy and safe water for all over the world.

-

Small EDM Wire Cut Machine

Contact UsEconomic high speed edm wire cut machine.

Main Features:

Roller for X/Y axis, also called hard rail ( V rail);

With ±3° taper as standard, ±15°, ±30°, ±45° as option;

Accuracy: ±0.01/300mm;

Roughness: Ra 1.0-2.5 µm;

Low consumption, material saving. -

PP PE LDPE HDPE Film Recycled Plastic Washing Machine Recycling Production Line For Sale

Contact UsThe recycling washing line is mainly used to recycle all kinds of plastics, such as film, agricultural film, greenhouse film, woven bags and etc. it can also recycle waste plastic bottles such as HDPE, LDPE, PP, etc. Our output ranges from 300 kg to 2000 kg per hour. Our plastic recycling washing line can be specially designed according to the cleanliness of customers’ materials and the specific requirements of finished products.

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line.

Reviews

There are no reviews yet.