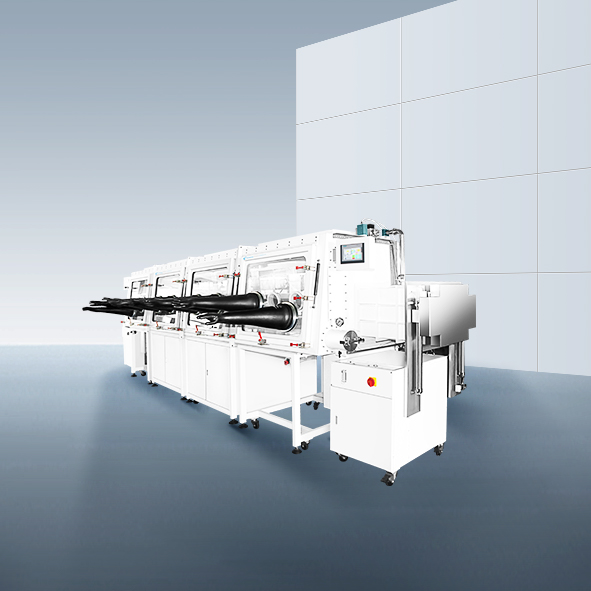

Solid state battery R&D production line

It can meet the needs of evaluation and screening of solid-state battery materials as well as development and testing of finished battery cells

It can be used to verify the process of converting the electrolyte from liquid to semi-solid and finally achieving all-solid state;

Meet the requirements for verification and performance testing of solid-state batteries of various systems such as polymers, oxides and sulfides as well as the preparation of metal lithium batteries.

The Solid State Battery R&D Production Line from Mikrouna is specifically engineered for forward-looking research and small-scale production of advanced solid-state batteries. This versatile line enables full-process experimentation and process verification—from the transformation of liquid electrolytes to semi-solid and ultimately all-solid-state electrolytes. It provides a reliable and controlled environment for testing and optimizing next-generation battery chemistries.

This production line is suitable for validating and preparing solid-state batteries of various systems, including polymer-based, oxide-based, and sulfide-based solid electrolytes, as well as for the development of lithium metal batteries. It offers flexible configuration and system integration tailored to the specific needs of R&D institutions and pilot-scale manufacturers, accelerating innovation and commercialization of solid-state battery technologies.

Key Features:

-

Supports process conversion verification from liquid to all-solid-state electrolyte systems

-

Compatible with multiple electrolyte systems: polymer, oxide, sulfide

-

Enables R&D and performance validation of lithium metal and solid-state batteries

-

High safety and environmental control standards for sensitive materials

-

Customizable modules to meet diverse research workflows and test parameters

-

Designed for small-scale pilot production and scalable experimentation

About Mikrouna

The Mikrouna lithium battery equipment team specializes in delivering full-process intelligent equipment solutions, including:

-

Pilot line systems for various solid-state battery technologies

-

Integrated solutions for lithium metal battery manufacturing

-

Advanced equipment for dry electrode preparation and lithium metal anode material development

-

Modular systems supporting the transition from R&D to mass production

With extensive experience in battery R&D automation, Mikrouna is committed to enabling innovation across the next generation of battery technologies through robust, customizable, and intelligent equipment solutions.

Related products

-

RO EDI

Contact UsOrisun group is specialize in supplying one stop solutions for whole manufacture chain. developing and manufacturing reverse osmosis water treatment for over 20 years.Our equipment is widely used in pharmacy industry , food and beverage industry , cosmetic industry , chemical industry, etc.As a leading provider of water treatment solutions ,our mission is to supply clean , healthy and safe water for all over the world.

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

12Kg Medium Torque Brushless Electric screwdriver Trigger start type

Contact UsBrushless DC voltage automatic medium torque electric screwdriver series

Model: GW-B6212LF

Torque: 2~12Kgf.cm

Free Speed: HI 2000 / LO 1500 r.p.m

Reviews

There are no reviews yet.