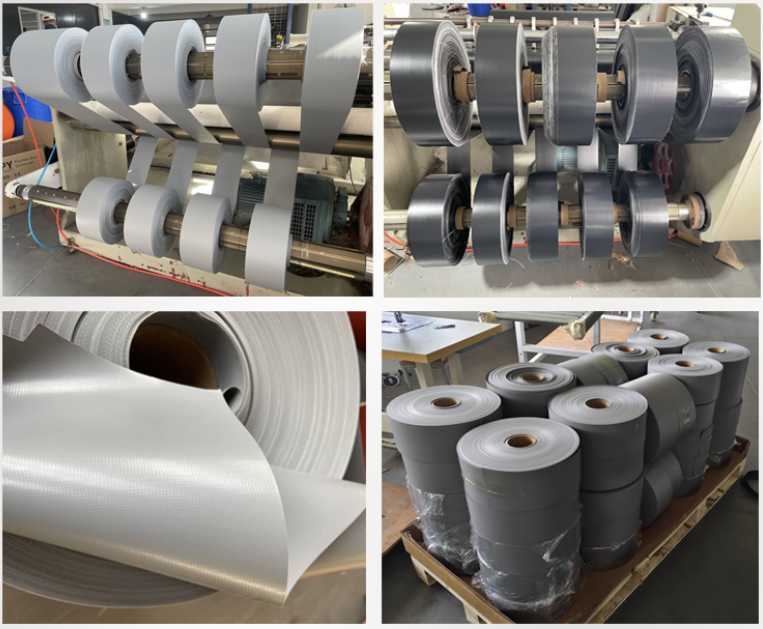

PVC Coated Cloth for HVAC

Product Details:• Place of Origin: Jiangsu China• Brand Name: Pinyi• Certification: ISO 9001, SGSPayment & Shipping Terms:• Minimum Order Quantity: 100 Meter

Products Introduction:

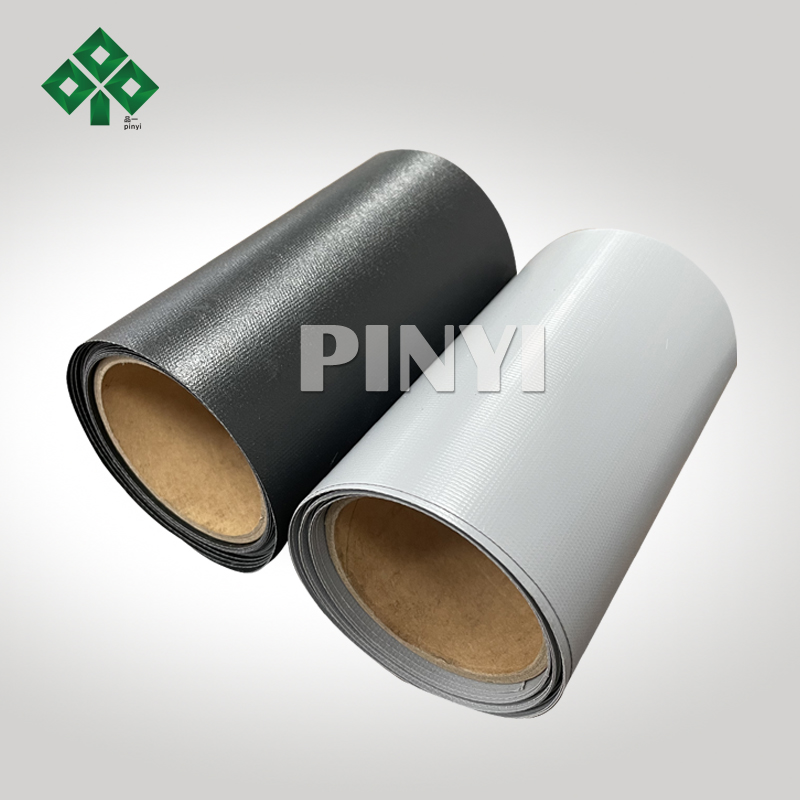

PVC coated cloth for HVAC is a high-performance composite material specifically engineered for heating, ventilation, and air conditioning systems. It consists of a durable base fabric (typically polyester or fiberglass) coated with polyvinyl chloride (PVC) through advanced processes like calendaring or laminating, resulting in a flexible, robust material designed to meet the rigorous demands of HVAC applications.

Key Features:

-

Excellent Air tightness: The seamless PVC coating ensures minimal air leakage, optimizing airflow efficiency in ductwork and reducing energy loss.

-

Moisture resistance: The PVC layer provides a reliable barrier against moisture, preventing condensation buildup and protecting the underlying fabric from water damage, which is crucial for maintaining HVAC system hygiene.

-

Durability: Resistant to wear, tear, and abrasion, this cloth can withstand the mechanical stress of installation, operation, and maintenance in HVAC environments.

-

Temperature tolerance: It performs well within a wide range of temperatures commonly encountered in HVAC systems, from moderate cold to high heat, without compromising its structural integrity.

-

Chemical resistance: The PVC coating offers protection against common HVAC cleaning agents, oils, and mild chemicals, ensuring long-term performance.

-

Flexibility: Easy to cut, fold, and install, adapting to various duct shapes and sizes, including curved or irregular configurations.

Applications in HVAC Systems:

-

Air duct liners: Used as a lining material for air ducts to enhance insulation and air tightness, improving overall system efficiency.

-

Duct wraps: Wrapped around ductwork to provide thermal insulation and protect against external moisture, reducing heat loss or gain.

-

Air handling unit covers: Serves as protective covers for air handling units, shielding internal components from dust, moisture, and debris.

-

Flexible connectors: Acts as flexible joints in duct systems, allowing for movement and vibration absorption while maintaining air tightness.

Reasons to Choose Us:

-

Our materials have been continuously updated with high-quality materials and superior craftsmanship based on feedback from over 10 years of merchant usage. This ensures that the products can satisfy our customers.

-

We are a manufacturing enterprise. By eliminating the price differences between manufacturers and intermediaries, product quality can be controlled, ensuring the maximum benefit for our customers.

-

We can tailor the most suitable materials and sizes for you according to your requirements.

-

We have a professional technical team. From material selection to product development, and even after-sales service, there are systematic procedures in place, ensuring that customers can purchase with peace of mind.

-

Our factory is a professional manufacturer of glass fiber products and can establish a long-term and stable cooperative relationship with customers.

Related products

-

Acrylic coated fiberglass cloth

Contact UsProduct Details:• Place of Origin: Jiangsu China• Brand Name: Pinyi• Certification: ISO 9001, SGSPayment & Shipping Terms:• Minimum Order Quantity: 100 Meter

-

Station type dry mixed mortar production line

Contact UsJiangjia Construction Machinery has accumulated more than 30 years of technical experience in producing drying and mixing equipment, targeting new technologies, materials, and products from foreign peers today. With independent innovation and the innovative concept of catching up with the international market, it has successfully developed the high-quality, high-efficiency, low-energy consumption, and environmentally friendly DZG series dry mix (powder) mortar production line. Since its launch on the market, the product has received high praise from domestic and foreign users, and has provided products and services to more than 300 customers at home and abroad.

-

Semi Matte Cotton-Linen Canvas

Contact UsCotton canvas is a durable, versatile fabric from cotton, ideal for bags, art, and decor, valued for its strength and timeless appeal.

-

Wh American Standard Hollow Metal Commercial Fire Door for Apartment

Contact UsWh American Standard Hollow Metal Commercial Fire Door for Apartment

Reviews

There are no reviews yet.