NZ-03 Nano-polyester for Drilling Fluid

NZ-03 is a multi-polymer composed of alkane sulfonate, alkyl ester, crosslinking agent. It forms nano-solid sealing material through special technology. The special functional groups on the molecular chain has strong adsorption ability, and strong adhesion properties. NZ-03 reduces pore-pressure transmission by sealing pore throats and micro-fractures due to reasonable size distribution of NZ-03 in muds. It can be used in various water-base drilling fluids. Its recommend dosage is 1.0 – 3.0% (v/v).

Product Description

NZ-03 is a multi-polymer composed of alkane sulfonate, alkyl ester, crosslinking agent. It forms nano-solid sealing material through special technology. The special functional groups on the molecular chain has strong adsorption ability, and strong adhesion properties. NZ-03 reduces pore-pressure transmission by sealing pore throats and micro-fractures due to reasonable size distribution of NZ-03 in muds. It can be used in various water-base drilling fluids. Its recommend dosage is 1.0 – 3.0% (v/v).

Technical Specification DBW NZ-03

|

Items |

Specifications |

|

Appearance |

White Emulsion |

|

FLAPI, mL |

≤15.0 |

|

Particle size D50 after 150℃/16h aging, μm |

≤0.9 |

|

Penetration Index, mm |

≤0.5 |

Features

Form semipermeable membrane at the borehole interface and cutting surface, to maintain the stability of borehole and integrity of the cuttings.

Excellent performance of borehole stability, it can be applied to all kinds of strong water- sensitive and other complex formation.

Resist high temperature up to 200 ℃ and reduce HTHP filtration loss.

Compatible with other additives well.

Low fluorescence, can be applied to exploration wells.

Package and Storage

It is a liquid packaged in 200 liter blue can. International packaging may vary. And they shall be stored in a shady and dry place with good ventilation.

Safety

They shall be avoided contact with eyes, skins and clothes, otherwise flush it with water. Handling methods and dangerous data shall be referred to MSDS.

Related products

-

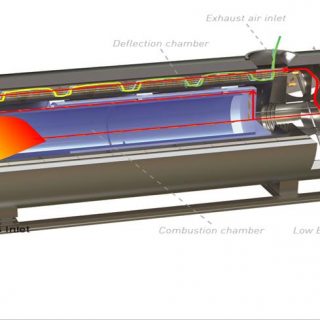

TNV direct fired incinerator

Contact UsDesign and manufacture by using the German EN12753 safety standard and the European ED. It is used Metal Painting and Printing LED Drying:

1. For stable industrial and mining conditions with a high temperature concentration of 1.5g/M3 or above.

2. Industrial and mining conditions with requirements for thermal energy recovery and utilization.

3. Industrial and mining conditions required for the operation of independent drying rooms.

4. Special effects on projects that reduce emissions and increase production -

Gel sealed Mini-pleat HEPA filter(Peripheral gel seals)

Contact UsThe two-component gel is poured into the liquid seal type HEPA filter , and this is used as an installation seal.

-

KSZ-1.5S1/S2 Welding Fume Extractor

Contact UsFeatures:

● High efficiency custom aluminum impeller

● Self-supporting & self-positioning suction hood

● Durable flexible suction arm, high temperature resistance & flame retardant & abrasion resistance

● Easy to replace and clean filters, no frequent maintenance is required

● Imported filter material with high precision filtration

● Special designed dust cleaning device, automatic blow-back cleaning

● Siemens PLC smart control system, more intelligent and energy saving

● Integrated automatic fire extinguish system -

Hazardous waste incineration device project

Contact UsThis project plans to build a treatment of 50,000 tons of organic substance solvents comprehensive recycling and utilization project hazardous waste incineration device, to incinerate the hazardous waste generated by the our factory and for receiving waste from other companies.

Reviews

There are no reviews yet.