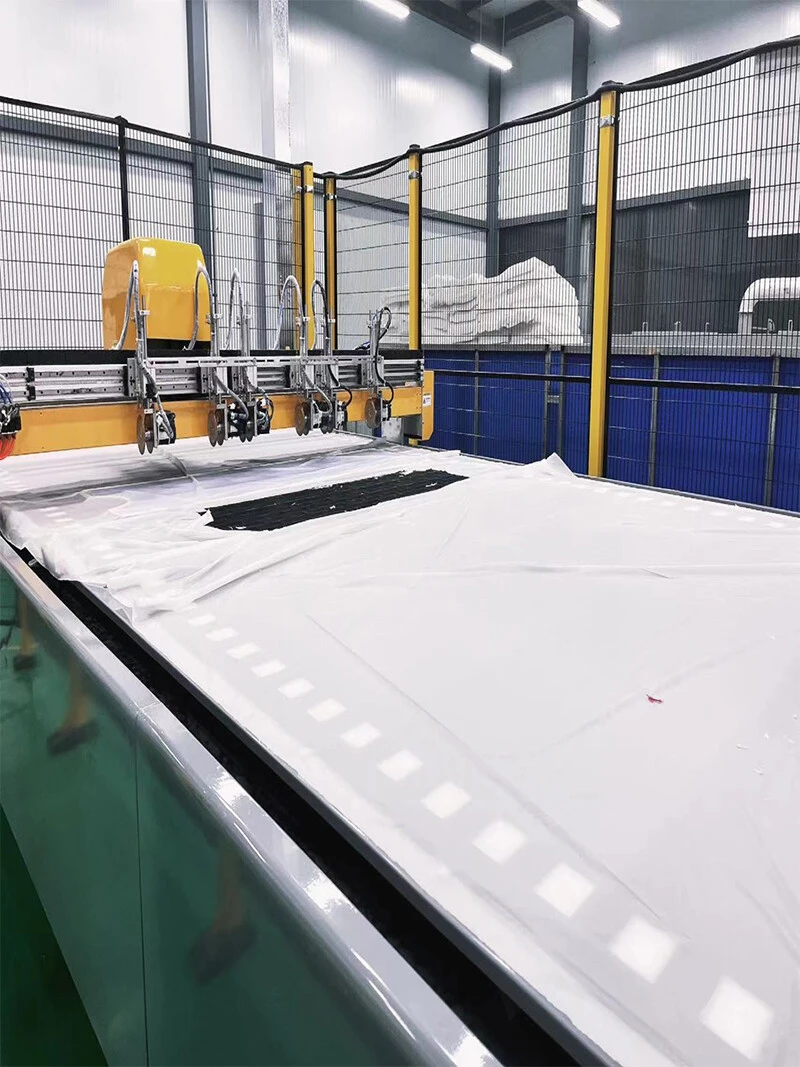

Multi-functional cutting machine

The multi-functional cutting machine is a highly integrated digital cutting device in modern manufacturing. It is no longer confined to cutting a single material. Instead, by changing different tool heads and processing software, it can achieve precise, efficient and automated cutting, drawing, engraving and other operations on various soft and hard boards. It is one of the core equipment for small-batch, multi-variety flexible production.

Multi-functional cutting machine

Function and role

This model is applied to the cutting of sheet materials such as non-woven

fabrics, sealing gaskets, cardboard, etc.

It has the advantages of reducing labor costs, increasing production

capacity, improving product quality, and automatically discharging materials to

reduce material waste. It features high speed and precision, solving the problem

of difficult manual cutting.

3. It can replace manual operation, substitute 4 to 6 people, with high

cutting accuracy and perfect effect.

4. It can work continuously for 24 hours, with high efficiency and high

output.

5. It can automatically layout, save materials and improve the utilization

rate of materials.

6. Grooves can be made and the cutting depth can be controlled.

Equipment parameters

|

Land occupation |

8500mm*2600mm*1280mm(L*W*H ) |

|

Ground requirements |

The ground is flat. |

|

Equipment weight |

1000KG |

|

Total power of the equipment |

11KW |

|

Power supply |

380V/50Hz 220V/50Hz |

|

Exhaust ventilation |

The exhaust port of the vacuum pump leads to the outside |

|

PC |

Ordinary desktop computers and monitors |

Related products

-

-

PP PE LDPE HDPE Film Recycled Plastic Washing Machine Recycling Production Line For Sale

Contact UsThe recycling washing line is mainly used to recycle all kinds of plastics, such as film, agricultural film, greenhouse film, woven bags and etc. it can also recycle waste plastic bottles such as HDPE, LDPE, PP, etc. Our output ranges from 300 kg to 2000 kg per hour. Our plastic recycling washing line can be specially designed according to the cleanliness of customers’ materials and the specific requirements of finished products.

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

Reviews

There are no reviews yet.