Hard Surface Wear-Resistant Coating

The coating includes plasma spraying ceramic wear-resistant coating and supersonic flame spraying carbide cermet coating.

The coating includes plasma spraying ceramic wear-resistant coating and supersonic flame spraying carbide cermet coating.

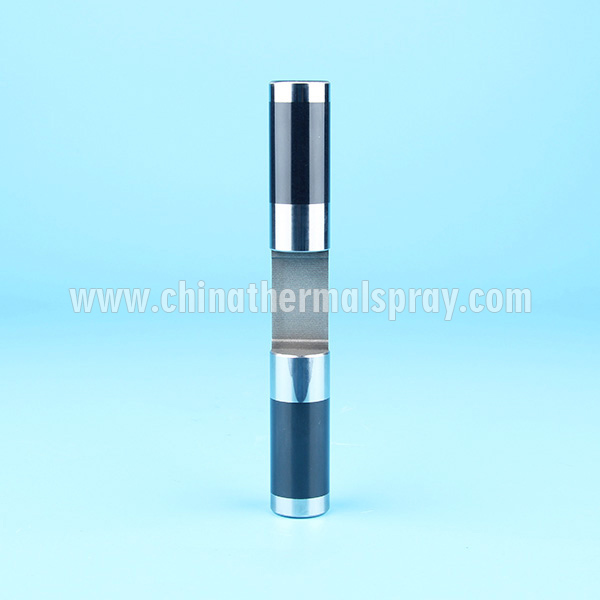

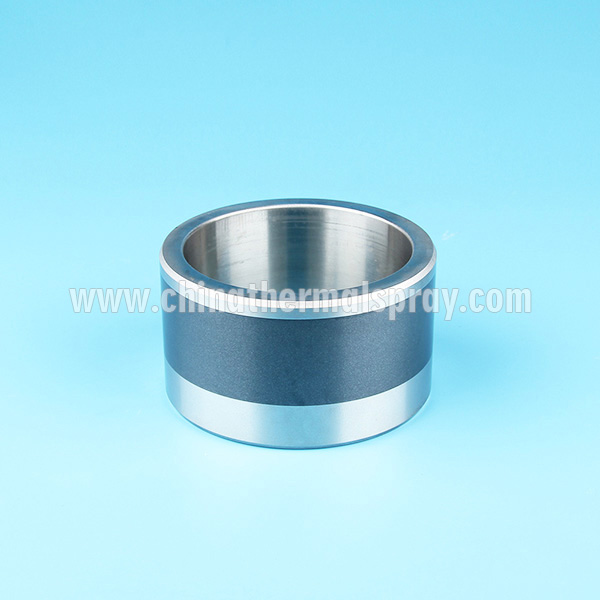

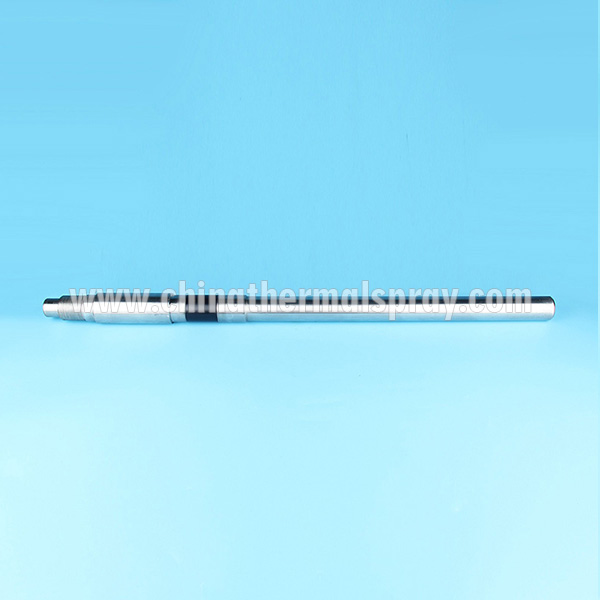

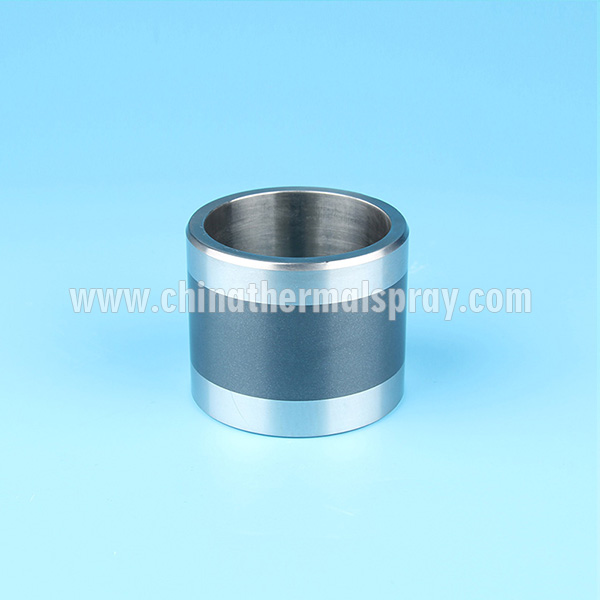

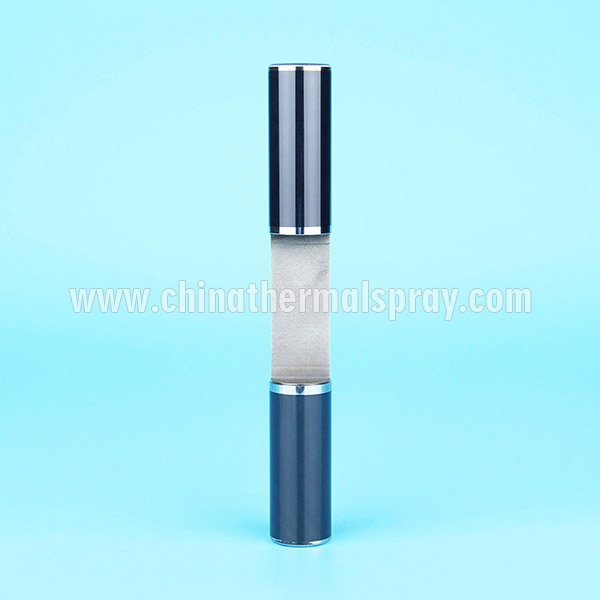

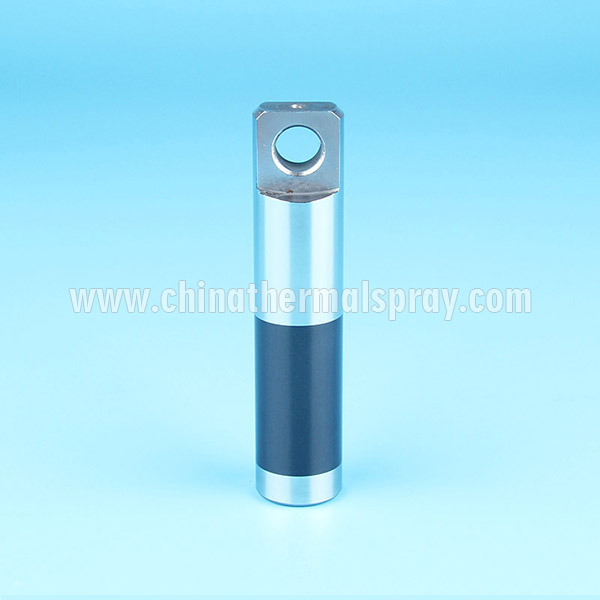

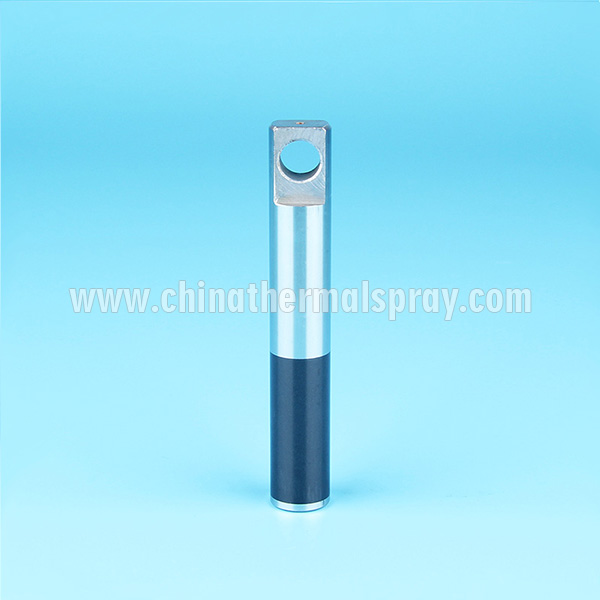

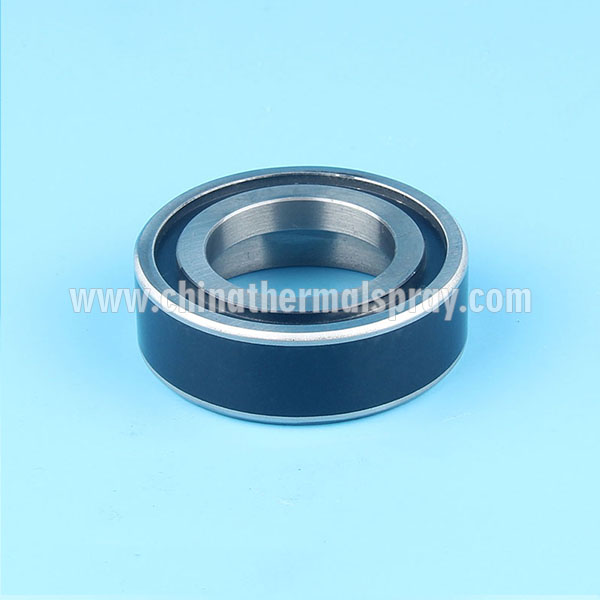

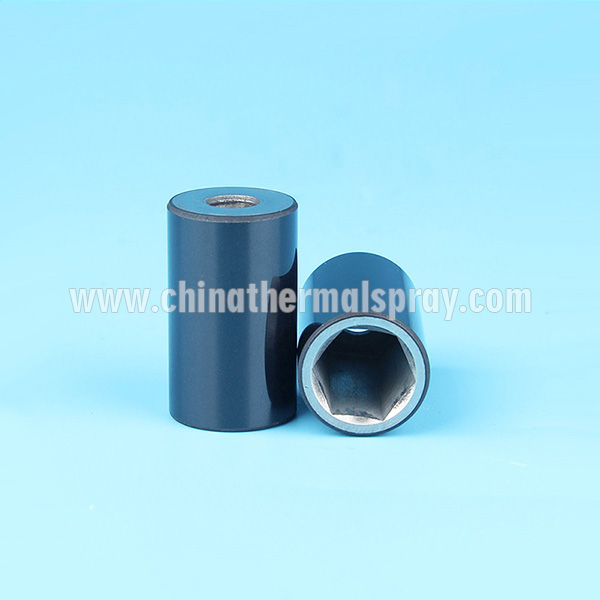

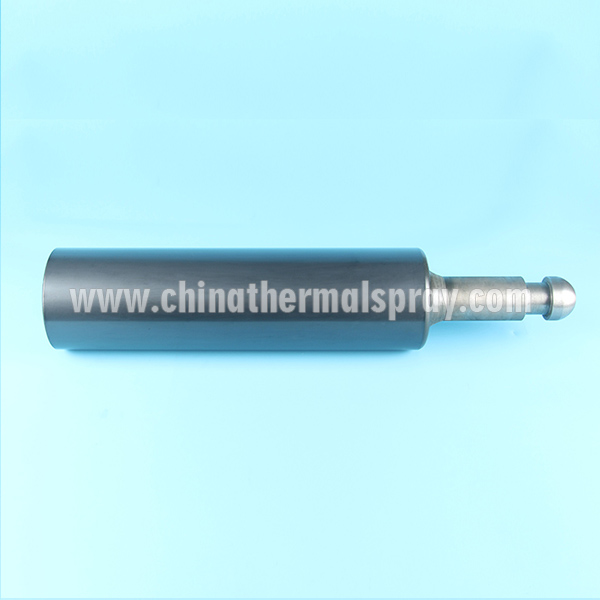

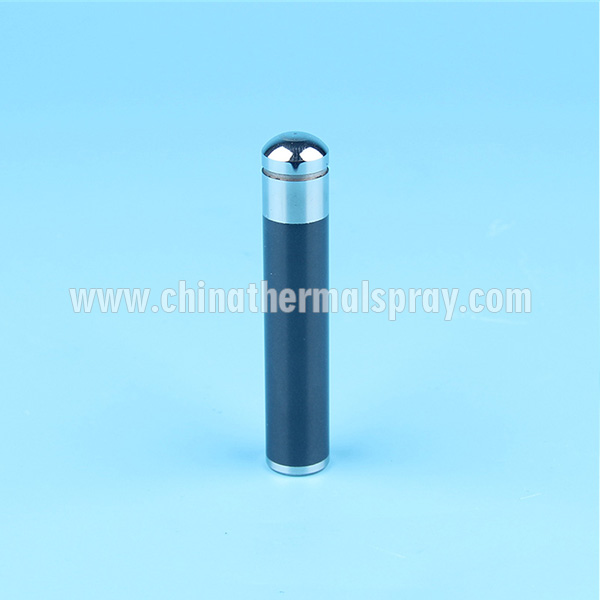

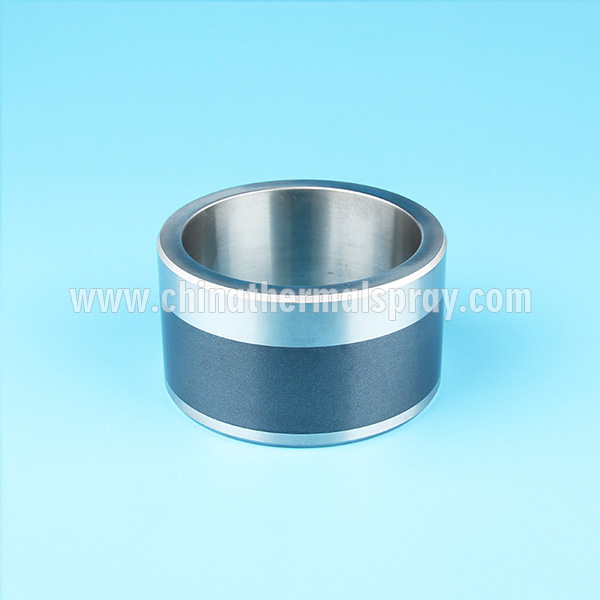

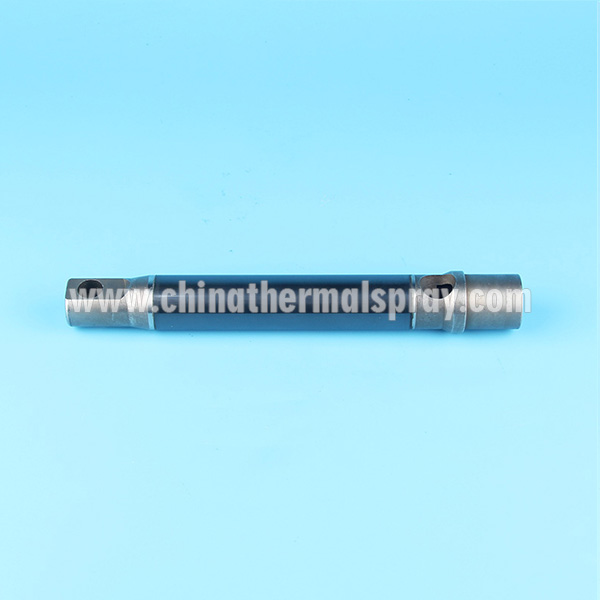

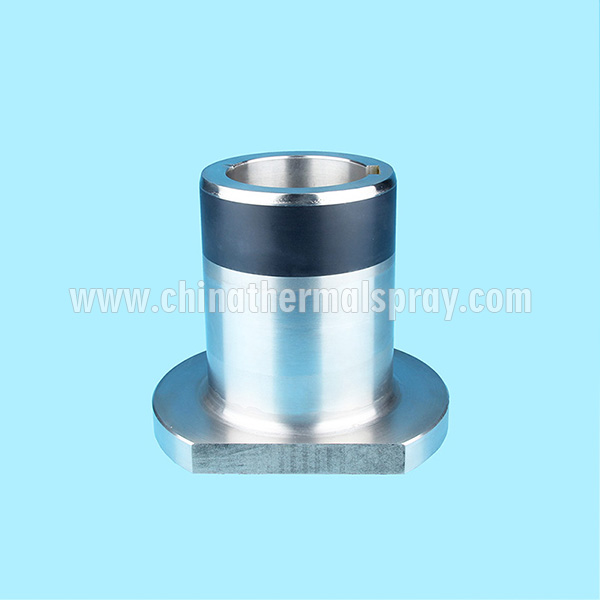

The ceramic materials used in plasma spraying are mainly alumina-titanium/chromia series oxide ceramics. Such materials have outstanding properties such as high hardness, corrosion resistance, good heat resistance, and low friction coefficient. The coating structure is dense, and the surface can be polished to a mirror surface (Ra0.03-0.10 μm). For example, a 0.3-0.5 mm thick ceramic coating is sprayed on the surface of the high-pressure pump plunger, and its service life is 6 longer than that of the conventional hard chrome-plated plunger. times, is the most widely used ceramic coating.

Supersonic flame spraying cermet coating which composites nickel-chrome, cobalt base metal phase and tungsten carbide, chromium carbide etc. hard phase ceramic materials, has the characteristics of high hardness, good toughness and shock resistance etc. Its bonding strength can reach 50-80MPa.

Application:

Plunger pump plunger, high pressure cleaning machine plunger, agricultural sprayer plunger, various water seal oil seal shaft sleeves, various shaft seal sections, etc.

Coating material:

-

AT13 (Al2O3/TiO2 87%/13%): High hardness, good wear resistance.

-

Cr2O3: High hardness, low friction coefficient, good corrosion resistance, abrasive wear resistance.

-

Co-WC: Good high temperature red hardness, abrasive wear resistance, erosion resistance.

-

Ni-WC: High hardness, high temperature oxidation resistance.

Related products

-

ATLAS COPCO 3001500626 MPV KIT

Contact UsWe are ATLAS COPCO 3001500626 MPV KIT supplier and provide replacement parts for major air compressor manufacturers.

-

ATLAS COPCO 1621304400 PIPE ZR/ZT

Contact UsWe are ATLAS COPCO 1621304400 PIPE ZR/ZT supplier and provide replacement parts for major air compressor manufacturers. Please feel free to contact us at henry.guan@foxmail.com with any questions of t

-

Aerospace gear manufacturers

Contact UsThe company’s main products are high precision involute cylindrical gears,We specialize in manufacturing of gears products such as spur gear,helical gear, herringbone gear, external spline..

-

DIN-EN 856 4SP

Contact UsSTANDARD: SAE J517 TYPE 100 R12

TUBE: oil resistant synthetic rubber

REINFORCEMENT: four spiral high strength stainless steel wire

COVER: oil, abrarion & weather resistant synthetic rubber

TEMPERATURE RANGE: -40℃ /+100℃ ; -40 °F/+212°F LT-55 & HT150℃ customizable

APPLICATION: suitable for high temperature and medium pressure hoses under harsh conditions, machine tools and agricultural applications, construction machinery, oil drilling, mining machinery, steel, chemical industry, energy, rail transit, food processing and shipbuilding

Reviews

There are no reviews yet.