Polyaluminum Chloride

Polyaluminum chloride (drinking water grade) is a kind of inorganic polymer coagulant.

Polyaluminum chloride (drinking water grade) is a kind of inorganic polymer

coagulant. It mainly makes fine suspended particles and colloidal particles

destabilize, aggregate, flocculate, coagulate, and precipitate through the

mechanism of compression, adsorption electric neutralization, and substrate net

trapping, which achieve the effect of purification.

Polyaluminum chloride (drinking water grade) is a light yellow powder, its

quality meets the standard.

|

Items |

Indicators |

|

Appearance |

Light yellow powder |

|

Aluminium oxide AL2O3(%) |

≥ 29 |

|

pH value |

3.5-5.0 |

|

Water-insoluble substance(%) |

≤ 0.6 |

Advantages:

1. Wide range of applications;

2. Easy to form a good flocculation state quickly; good precipitation

performance;

3. The PH range of adaptation is wide, and the PH value and alkalinity of the

treated water have a small decrease;

4. When the water temperature is low, it can still maintain a stable

precipitation effect;

5. Small erosion effect on the equipment.

Usage:

The product is widely used in drinking water, medicine, food, sanitation, and

other water treatment.

Related products

-

KSZ-1.5S1/S2 Welding Fume Extractor

Contact UsFeatures:

● High efficiency custom aluminum impeller

● Self-supporting & self-positioning suction hood

● Durable flexible suction arm, high temperature resistance & flame retardant & abrasion resistance

● Easy to replace and clean filters, no frequent maintenance is required

● Imported filter material with high precision filtration

● Special designed dust cleaning device, automatic blow-back cleaning

● Siemens PLC smart control system, more intelligent and energy saving

● Integrated automatic fire extinguish system -

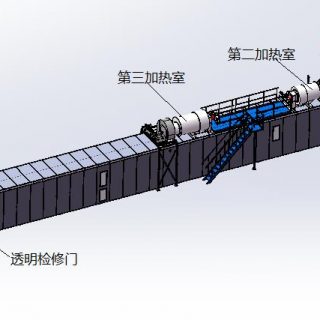

Metal sheet drying oven for can making

Contact UsThe oven is mainly used to dry the coating on the tin (or aluminum) sheet in the can making process. The entire line mainly consists of conveying, feeding devices, drying, cooling, and material collection and stacking.

-

External Suction Arm

Contact UsFeatures:

● Persistent tightness

● Arm keeps position due to self-supporting design

● Fast operation due to particularly flexible adjustment

● User-friendly due to particularly smooth movement of the hood with one hand

● Various options to connect the exhaust arms to fans, stationary devices or via duct work to central extraction and filtration systems -

Hazardous waste incineration device project

Contact UsThis project plans to build a treatment of 50,000 tons of organic substance solvents comprehensive recycling and utilization project hazardous waste incineration device, to incinerate the hazardous waste generated by the our factory and for receiving waste from other companies.

Reviews

There are no reviews yet.