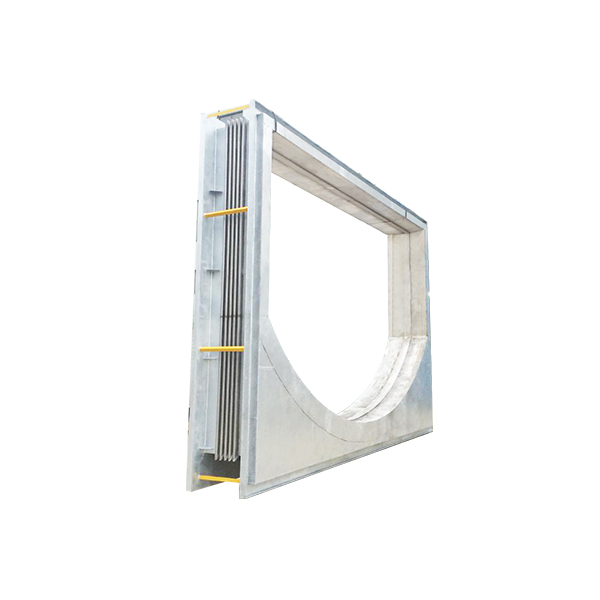

Shaped Bellows Expansion Joint

Rectangular bellows can absorb axial displacement, angular displacement, lateraldisplacement and displacement made of any combination of them.

Shaped Bellows Expansion Joint-Rectangular bellows can absorb axial displacement, angular displacement,

lateraldisplacement and displacement made of any combination of them;

The corners of the rectangular bellows are usually rounded, right-angled,

double obtuseand folded. The waveform (CE waveform) has full height and half

height.The commonly used materials are weathering steel, austenitic stainless

steel, and ordinary carbon steel;

This bellow is mainly used for displacementcompensation of square pipes.

Smoke ducts, fan inlets and outlets, dust collector inletand outlet pipes, and

various exhaust gas pipes are often used.

Operating pressure:30~ 200KPa

Related products

-

VMC 500 CNC Vertical Machining Center

Contact UsThe machine is suitable for communication, medical equipment, power tools, 3C products processing,etc.Three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.

-

Waste Tyre Recycling Production Line

Contact UsPresently, waste tire recycling equipment provided by our domestic competitors usually can produce 20-40 meshe rubber powder under normal temperature.

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line.

Reviews

There are no reviews yet.