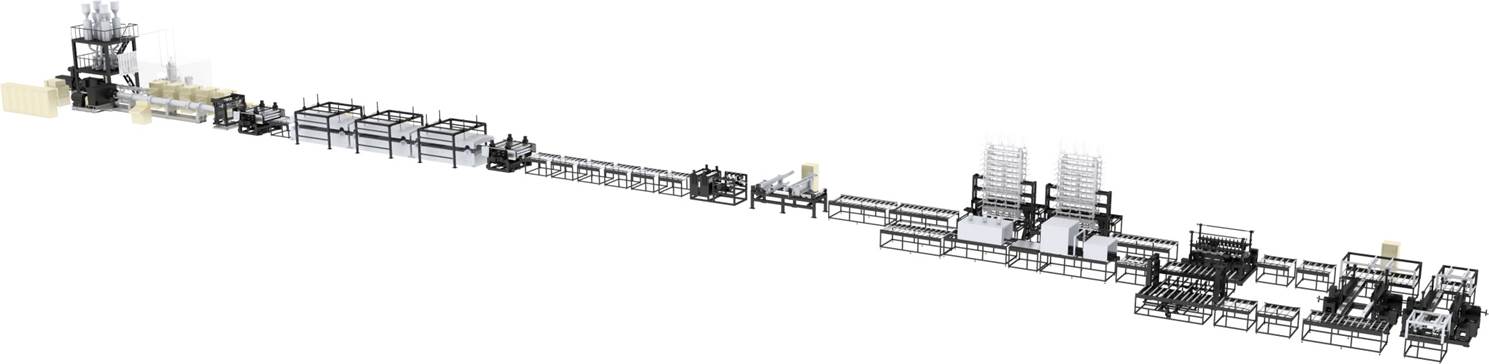

XPS foam board production line

The supercritical carbon dioxide foaming XPS production line is a type of production line used to produce XPS (extruded polystyrene) panels.

Supercritical CO2 foaming XPS production line.

The supercritical carbon dioxide foaming XPS production line is a type of

production line used to produce XPS (extruded polystyrene) panels. This

production line uses supercritical carbon dioxide (CO2) as a foaming agent. By

heating the CO2 gas to a supercritical state, it is dissolved in the polystyrene

resin to form bubbles, thereby achieving the foaming forming of the panel. Its

advantages include the following aspects:

-

Better control of the uniformity and quality of the material, reducing the

defect rate of the product; -

It has high flexibility and adjustability, and can adapt to the production

needs of different materials and products; -

The upgrade of the control system makes the operation of the production

line more stable and reliable.

Parameter Table

|

Model |

Capacity(kg/h) |

Transformer Required |

|

KFTS-65/150 |

200-350 |

250 KVA |

|

KFTS-75/160 |

200-450 |

300KVA |

|

KFTS-75/200 |

400-600 |

400KVA |

|

KFTS-85/200 |

500-800 |

450KVA |

|

KFTS-95/250 |

800-1200 |

550KVA |

|

KFTS-110/300 |

1000-1500 |

600KVA |

Related products

-

20KVA/16KW Diesel Generator With Cummins Engine

Contact UsOur 16KW 20KVA diesel generator with Cummins engine is ideal for reliable power solutions.

-

RO EDI

Contact UsOrisun group is specialize in supplying one stop solutions for whole manufacture chain. developing and manufacturing reverse osmosis water treatment for over 20 years.Our equipment is widely used in pharmacy industry , food and beverage industry , cosmetic industry , chemical industry, etc.As a leading provider of water treatment solutions ,our mission is to supply clean , healthy and safe water for all over the world.

-

Optimizing Cross Cut Saw MAXCUT CS15/15XL

Contact UsMAX CUT CS15/15XL, as a relatively practical type of cross cut saw, it is designed for the bending timber, such as rubber wood.

-

MA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment

Contact UsMA-(0.8~4MM)×1300MM Steel Coil Slitting Equipment can process the slitting of the coil with different sizes to small strips for processing various kinds of metal coil materials.

Reviews

There are no reviews yet.