2205 Duplex Stainless Steel Plate

● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product’s size.

● We can make it as your requirement.

Profile

The yield strength of 2205 Duplex stainless steel is more than twice that of ordinary austenitic stainless steel, and it has enough plastic toughness required for molding. The wall thickness of storage tanks or pressure vessels made of duplex stainless steel is 30-50% less than that of commonly used austenite, which is conducive to reducing costs. Moreover, it has good local corrosion resistance, and compared with austenitic stainless steel with similar alloy content, its wear corrosion resistance and fatigue corrosion performance are better than austenitic stainless steel.

Whether under dynamic load or static load conditions, 2205 duplex stainless steel has a higher energy absorption capacity than austenitic stainless steel, which has obvious advantages for structural parts to cope with emergencies such as collisions, explosions, etc..

Product Description

|

Product |

2205 Duplex Stainless Steel Plate |

|

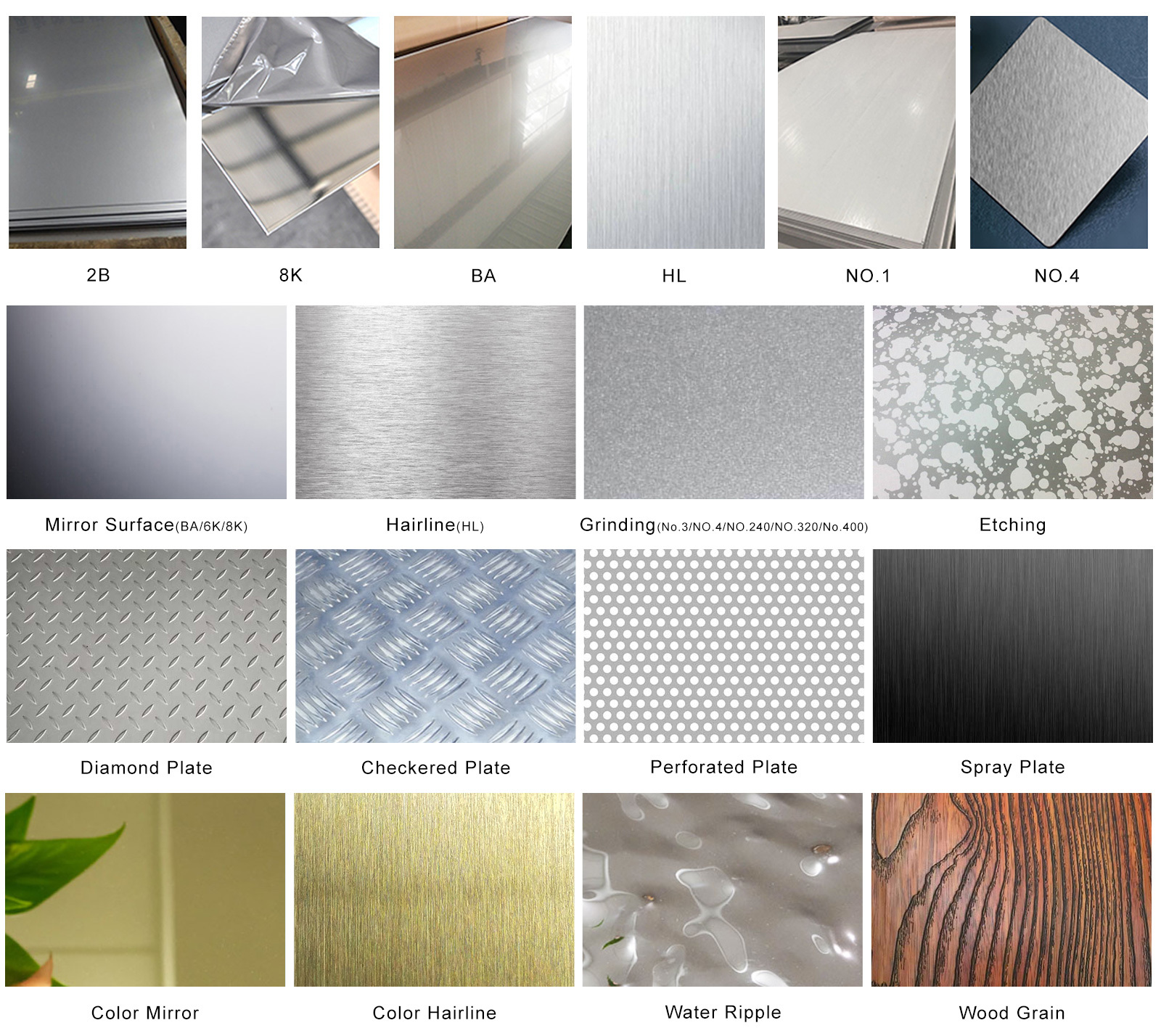

Surface Finish |

BA, 2B, 4K, 6K, 8K, NO.4, HL, Embossed, Perforated, Pickling white, Polished outside, Polished inside and outside |

|

Technique |

Hot Rolled / Cold Rolled |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

|

Width |

500mm/1000mm/1219mm/1250mm/1500mm/1800mm/2000mm/2200mm/2500mm/3000mm/3500mm, or as required |

|

Length |

500mm/1000mm/2000mm/2438mm/2500mm/3000mm/6000mm/8000mm—13000mm, or as required |

|

Thickness |

0.4/0.5/0.6/0.7/0.8/0.9/1.0/1.2/1.5/2.0/2.5/3.0/4.0/5.0/6.0/8.0/10.0/12.0/14.0/16.0—250mm, or as required |

|

Material |

201, 202 |

|

Color |

Standard RAL color: Red, Blue, White, Grey, Brick, etc. |

|

Stock Dimension |

Cold Rolled: 0.4-6.0mm*1000*2000mm/ 1220*2440mm/ 1250*2500mm/ 1500*3000mm, or as your request |

|

Service |

OEM, Customized processing service, Customized fabrication by drawings |

|

Processing Type |

Cutting, Bending, Stamping, Welding, CNC machining |

|

Cutting Type |

Laser cutting; Water-jet cutting; Flame cutting |

|

Protection |

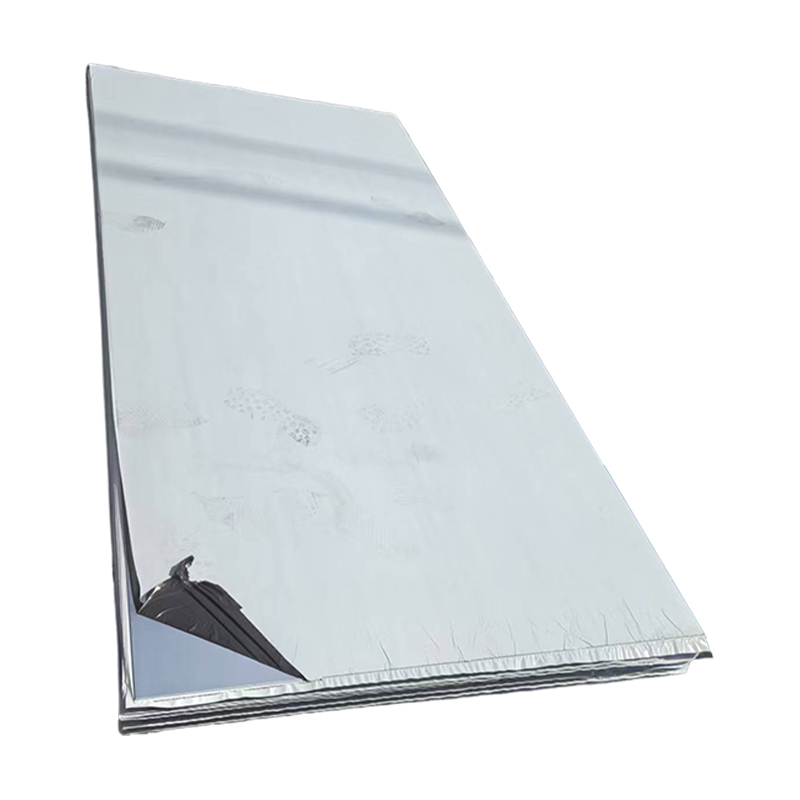

1. Inter paper available |

|

Application |

Costruction Industry/ Kichten Products/ Fabrication Industry/ Home Decoration |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

P |

|

≤ 0.03 |

≤1.0 |

≤ 2.0 |

21.0~23.0 |

4.5~6.5 |

2.5~3.5 |

≤ 0.02 |

≤ 0.03 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥620 |

≥450 |

≥25 |

≤ 293HB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.88 |

190 |

13.7 |

19.0 |

80 |

Surface Selection

Related products

-

Gr1 Gr2 Gr5 Titanium Alloy Plate/Sheet

Contact Us● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month; -

Customized Strong magnet de-ironing separator, N35-N52 grade

Contact UsSize: diameter from 1.5-70mm, length from 0.5-100mm. The magnet grade is at least N35.

Information in need: The magnet and the stainless steel grade, size, surface treatment, magnetizing direction, the quantity. Especially when the magnetic force and the temperature are in specific need. -

Different irregular shape NdFeB magnet, made as your drawing needs

Contact UsLength : 1.5mm to 70mm

Thickness: 1mm to 50mm

Material grade: The lowest is N35 -

316L Stainless Steel Plate

Contact Us316L stainless steel has a lower proportion of carbon in its composition. To qualify as 316L stainless steel, the amount of carbon cannot exceed 0.03%.

Reviews

There are no reviews yet.