WE67K-50/1500 Small CNC Press Brake

The model of this cnc press brake is ZDPE-5015 (WE67K-50/1500),with ZD-58 CNC control system,linear encoder,back gauge servo motors and other accessories are installed for perfect machine performance.

https://www.zdmt-machine.com/we67k-50t1500-small-cnc-press-brake.html

The model of this cnc press brake is ZDPE-5015 (WE67K-50/1500),with ZD-58 CNC control system, linear encoder, back gauge servo motors and other accessories of famous brand are installed for perfect machine performance.

Main Features

▪ Advanced proportional valve controls the hydraulic cylinders to work synchronously and achieve precise repeatability performance.

▪ Be capable of be controlled at random point within the stroke.

▪ Repeatability precision +/-0.01mm,parallelism precision +/-0.02mm.

▪ Deflection compensation table for high precision.

▪ ZD-58 CNC together with linear encoder, DP-TECH hydraulic system and other famous brand elements to ensure excellent performance.

▪ Quick clamps is for easy operation of removing and changing upper punch tools.

▪ X axis is controlled by servo motor,with strong synchronous belt,with high control accuracy,fast positioning and low noise.

▪ The backgauge installed with ball screw and linear rail,with high repetition accuracy and low maintenance.

Application

The application scope of press brake machine is very wide and they can be used in multiple industries and scenarios :

1. In the mechanical manufacturing industry, such as the processing of body panels in the automotive manufacturing industry;

2. Forming treatment used in the construction industry for manufacturing metal structural components such as railings and doors and windows;

On the electronic and electrical production line, it can be used for bending and shaping circuit boards as well as shaping and fixing coils, etc.

The production of various sheet metal parts in the hardware products industry also cannot do without the application of bending machines.

In fields such as aerospace, professional bending techniques are also required to process and shape special materials. In addition, bending machines can often be seen in some traditional industries such as light industry and textiles. In general, in any situation where thin metal sheets need to be bent, the application of a bending machine may be involved.

Main Specifications

| Model | 50/1500 | 70/2500 | 110/2500 | 110/3200 | 110/4000 | 130/3200 | 130/4000 |

| Bending force(KN) | 500 | 700 | 1100 | 1100 | 1100 | 1300 | 1300 |

| Bending length (mm) | 1500 | 2500 | 2500 | 3200 | 4000 | 3200 | 4000 |

| Columns distance (mm) | 1100 | 2050 | 1950 | 2650 | 3100 | 2650 | 3100 |

| Throat depth (mm) | 300 | 400 | 400 | 400 | 400 | 400 | 400 |

| Stroke (mm) | 150 | 170 | 200 | 200 | 200 | 200 | 200 |

| Open height (mm) | 340 | 360 | 385 | 385 | 385 | 385 | 385 |

| Main motor (kw) | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| Dimensions (mm) | 2100x1700x2200 | 3100x1800x2360 | 3200x1800x2650 | 3800x2000x2650 | 4800x2000x2700 | 3900x2100x2670 | 4800x2100x2700 |

| Weight (kg) | 2000 | 4800 | 6200 | 7000 | 8000 | 7300 | 8200 |

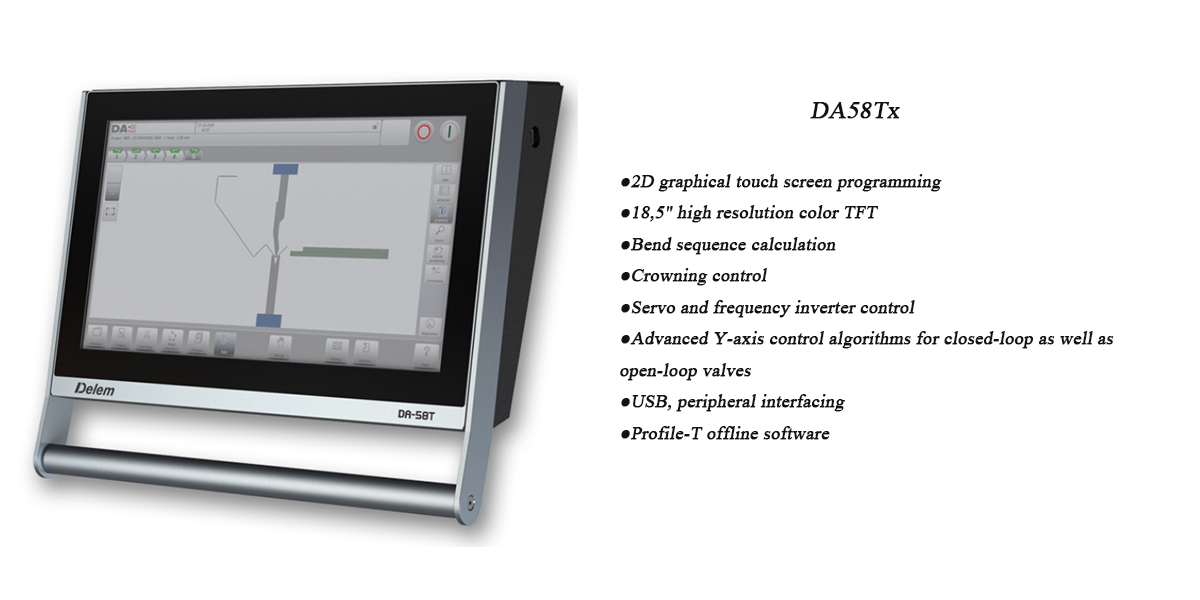

Optional control system

Company Profile

Related products

-

High-efficiency activated carbon attachment device

Contact UsHigh-efficiency activated carbon attachment device can quickly absorb pollutants in exhaust gas. The exhaust gas containing pollutants is powered by a fan and enters the activated carbon adsorber under negative pressure.

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board

Reviews

There are no reviews yet.