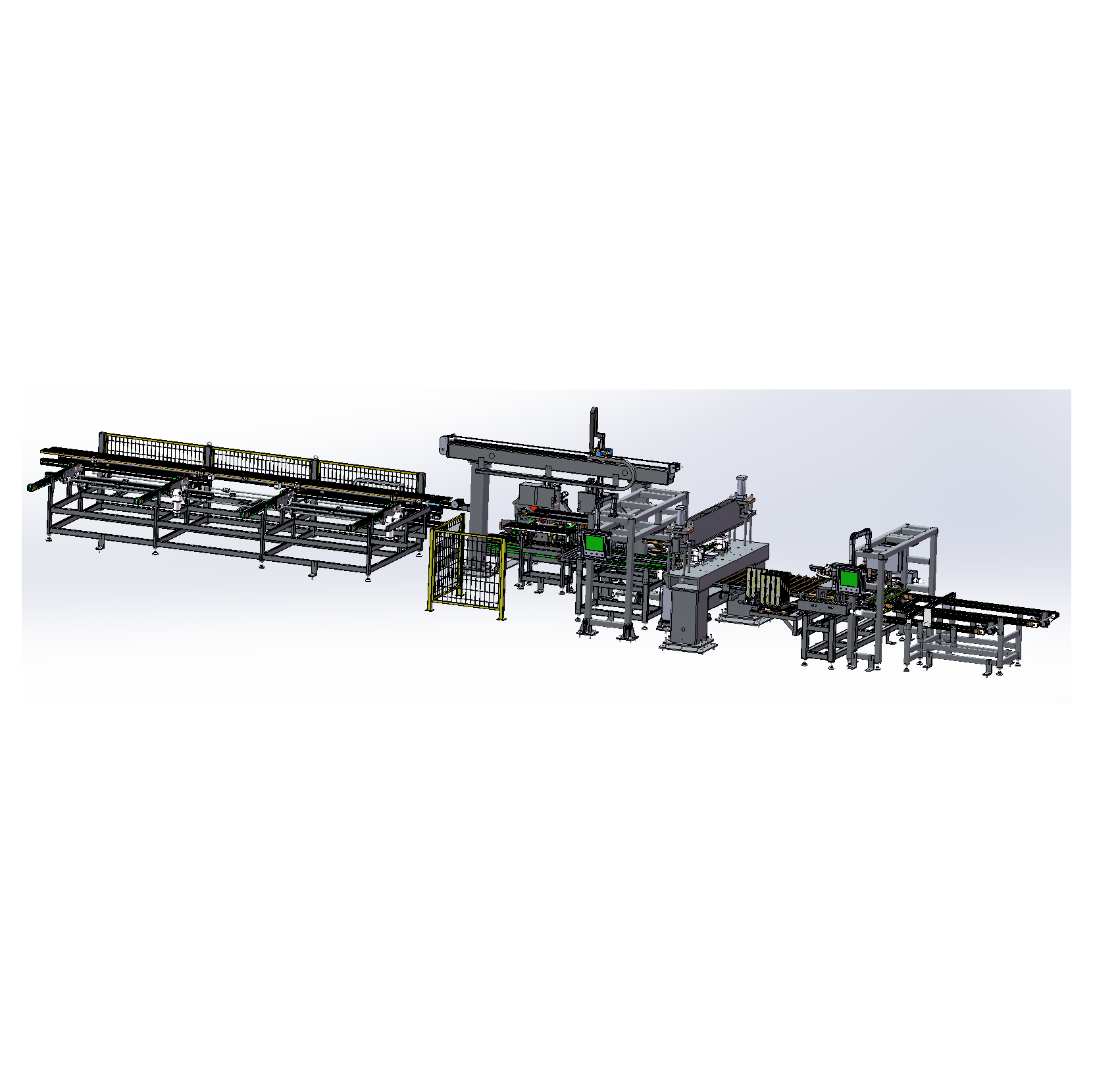

CLW-7000 automatic stamping production line of photovoltaic frame

CLW-7000 automatic stamping production line of photovoltaic frame is the 7th generation product launched by our company in 2025.

https://www.calowenauto.com/clw-7000-automatic-stamping-production-line-of-photovoltaic-frame.html

CLW-7000 automatic stamping production line of photovoltaic frame is the 7th generation product launched by our company in 2025.After more than 1 year of unremitting efforts,accumulation and reference,the company's R&D team has successfully developed anew generation of automatic stamping production line of photovoltaic frame,which has been significantly improved in production efficiency,product quality,energy saving and environmental protection, intelligent control and other aspects compared with the previous generation of production line.

Technical parameters

|

Name |

Automaticstampingproduction lineofphotovoltaicframe (longframe) |

Automaticstampingproduction lineofphotovoltaicframe (shortframe) |

|

Model |

CLW-25 |

CLW-15 |

|

Processinglengthrange(mm) |

1600~2500 |

990~1500 |

|

Processingsectionrange(mm) |

Bsidewidth:30-40,Csidewidth:10-35 |

|

|

Workingbeat(s) |

≤1.5 |

≤1.5 |

|

Angelaccuracy(°) |

±0.1 |

±0.1 |

|

Cuttinglengthaccuracy(mm) |

±0.15 |

±0.15 |

|

Qualifiedrateofprocessing |

99.8% |

99.8% |

|

Staffing(person/station) |

2.5 |

2.5 |

|

Ratedpower(kw) |

24 |

24 |

|

Externaldimensions(mm) |

16000×6000×2850 |

16000×6000×2850 |

Product advantages

1. The feeding method of sawing unit adopts the pulling material system,which improves the adaptability for twisted profiles.

2. The feeding of sawing unit is driven by electric cylinder,which effectively improves the processing quality of the workpiece.

3. The stamping molds only need to replace the punch head and inserted plate,which effectively reduces the costs.

4. Intelligent detection including length,mounting hole,bending,twisting,aluminium angle and water leakage hole detection.

5. Five sets of aluminium angle cartridges are set on one side of short frame stamping unit,and the aluminium angle capacity is greatly increased.

6. The finished products and defective products are automatically separated by upper and lower double-layer conveyor belt.

Related products

-

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

-

Waste Tyre Recycling Production Line

Contact UsPresently, waste tire recycling equipment provided by our domestic competitors usually can produce 20-40 meshe rubber powder under normal temperature.

-

RO EDI

Contact UsOrisun group is specialize in supplying one stop solutions for whole manufacture chain. developing and manufacturing reverse osmosis water treatment for over 20 years.Our equipment is widely used in pharmacy industry , food and beverage industry , cosmetic industry , chemical industry, etc.As a leading provider of water treatment solutions ,our mission is to supply clean , healthy and safe water for all over the world.

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

Reviews

There are no reviews yet.