Fixed Speed Basic Model Principle Type (FBM-P) Magnetic Coupling

● No physical connection between motor and load

● Reduce system vibration

● Accepts misalignment

● Overload protection

https://www.magicmag-tech.com/Fixed-Speed-Basic-Model-Principle-Type-FBM-P-Magnetic-Coupling.html

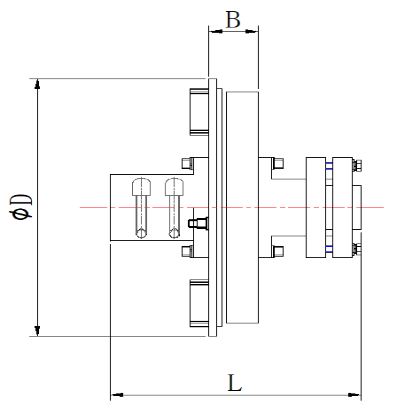

STRUCTURAL PATTERN:

PRODUCT DESCRIPTION:

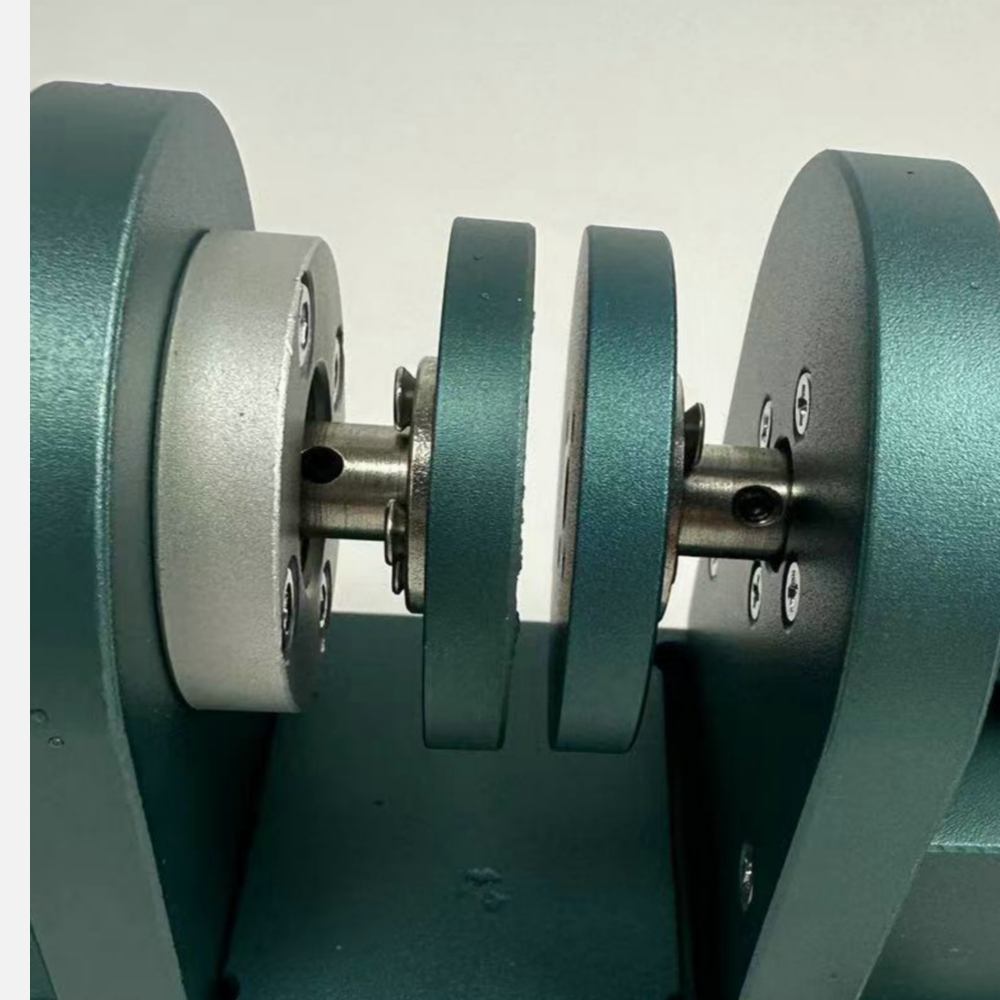

An FBM(P) consists of two separate components that have no physical contact. A precision machined aluminum rotor containing powerful permanent rare earth magnets is mounted on one shaft. A conductor consisting of a steel housing with copper rings mounts on the other shaft. The coupling’s ability to transmit torque is created by the relative motion between the copper conductor and the magnets. This motion creates a magnetic field in the copper that interacts with the permanent magnets, thus transmitting torque across the air gap.

● The motor can be moved at will

● Energy Savings

● Accepts Large Misalignment

● Cushioned Start

● Eliminates Vibration Transfer

● Absorbs Shock Loading

● Low Maintenance

● Simple Installation

● Reduces O&M Costs

● Increases Seal & Bearing Life

APPLICATION:

● Water

● Oil & Gas Power

● Generation

● HVAC

● Pulp & Paper

● Irrigation

● Mining & Cement

● Maritime

● Chemical Processing

SPECIFICATION:

|

Model |

Input Speed/ number of poles |

Rotating Power (kw) |

External dimensions |

Maximum Input Speed(r/min) |

Weight. (kg) |

|

|

Diameter (mm) |

Width (mm) |

|||||

|

FBM-A0002-04P |

1500/4 |

2.2 |

230 |

55 |

3000 |

11.6 |

|

FBM-A0003-04P |

1500/4 |

3 |

230 |

55 |

11.6 |

|

|

FBM-A0004-04P |

1500/4 |

4 |

230 |

55 |

11.6 |

|

|

FBM-A0005-04P |

1500/4 |

5.5 |

230 |

55 |

11.6 |

|

|

FBM-A0007-04P |

1500/4 |

7.5 |

230 |

55 |

11.6 |

|

|

FBM-A0011-04P |

1500/4 |

11 |

230 |

55 |

12.5 |

|

|

FBM-A0015-04P |

1500/4 |

15 |

230 |

55 |

13.4 |

|

|

FBM-A0018-04P |

1500/4 |

18.5 |

230 |

55 |

14.3 |

|

|

FBM-A0022-04P |

1500/4 |

22 |

230 |

55 |

15.2 |

|

|

FBM-A0030-04P |

1500/4 |

30 |

280 |

55 |

18 |

|

|

FBM-A0037-04P |

1500/4 |

37 |

280 |

55 |

18.9 |

|

|

FBM-A0045-04P |

1500/4 |

45 |

280 |

55 |

19.8 |

|

|

FBM-A0055-04P |

1500/4 |

55 |

280 |

55 |

21.4 |

|

|

FBM-A0075-04P |

1500/4 |

75 |

330 |

56.5 |

26 |

|

Note: The above data is for reference only, and the specific instalation dimensions are suplect

FAQ

Q1: What is the Fixed Speed Basic Model Principle Type (FBM-P) Magnetic Coupling?

A1: The Fixed Speed Basic Model Principle Type (FBM-P) Magnetic Coupling is a basic permanent magnetic coupling designed to simplify power transmission systems. It uses non-contact magnetic force to transmit torque, eliminating the vibrations and shocks associated with traditional rigid couplings. This basic type coupling is ideal for industrial applications requiring smooth start-up and low maintenance.

Q2: How does the FBM-P Basic Permanent Magnetic Coupling work?

A2: The FBM-P basic type coupling operates on the principle of magnetic induction. It features precisely engineered aluminum rotors and copper ring conductors that interact magnetically to transfer torque efficiently. This standard permanent magnet coupling allows for some axial and radial misalignment, ensuring smooth and reliable operation.

Q3: What are the key features of the FBM-P Magnetic Coupling?

A3: The key features of the FBM-P Standard Permanent Magnet Coupling include:

Non-contact operation: No physical contact between the motor and the machine, reducing vibration.

Misalignment tolerance: It can handle a certain degree of misalignment without damaging the equipment.

Low maintenance: Designed for up to 30 years of maintenance-free operation.

Smooth start-up: Delays torque transfer to ensure a gentle start, extending the life of the system.

Q4: What is the specification scope of the FBM-P Magnetic Coupling?

A4: The FBM-P Magnetic Coupling is suitable for low to medium power applications, with a maximum power rating of 11 kW. It is designed for use with 1500 r/min, 4-pole motors.

Q5: How does the Standard Permanent Magnet Coupling contribute to energy savings?

A5: The FBM-P Magnetic Coupling contributes to energy savings through its efficient magnetic induction system. By optimizing the transfer of torque with minimal energy loss, it can help save up to 70% of energy compared to traditional coupling systems.

Q6: What is the expected lifespan of the FBM-P Basic Permanent Magnetic Coupling?

A6: The FBM-P Magnetic Coupling is designed for a long service life of up to 30 years with almost zero maintenance required. This makes it a cost-effective solution for long-term industrial applications.

Q7: How does the FBM-P Magnetic Coupling protect against mechanical stress?

A7: The FBM-P Magnetic Coupling protects against mechanical stress through its smooth start-up feature, which delays torque transfer to reduce initial shock. It also absorbs load shocks and allows for thermal expansion, extending the life of mechanical seals and bearings.

Related products

-

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

PP PE LDPE HDPE Film Recycled Plastic Washing Machine Recycling Production Line For Sale

Contact UsThe recycling washing line is mainly used to recycle all kinds of plastics, such as film, agricultural film, greenhouse film, woven bags and etc. it can also recycle waste plastic bottles such as HDPE, LDPE, PP, etc. Our output ranges from 300 kg to 2000 kg per hour. Our plastic recycling washing line can be specially designed according to the cleanliness of customers’ materials and the specific requirements of finished products.

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.